Disinfection in Water Treatment

When we turn on the tap to get water or make tea or cook in our drinking water, we often overlook the complex treatment process behind the water. Engineers at water treatment plants make sure that the water becomes clean and safe, and a crucial part of that process is disinfection.

What step is disinfection in water treatment?

Disinfection is a key step in the water treatment process used to kill or remove microorganisms from water to ensure the safety of drinking or industrial water. Typically, disinfection is the final step in the water treatment process and its main purpose is to kill or remove pathogens such as bacteria, viruses and parasites from the water.

In a typical water treatment process, disinfection usually occurs after the following steps:

- Pre-treatment: Pre-treatment steps such as coagulation, flocculation, sedimentation and filtration are usually required to remove suspended solids and particulate matter before the water enters the disinfection stage.

- Purification: This step involves chemical treatment to remove organic matter, odors, color and other impurities from the water.

- Sedimentation: Some water treatment plants perform sedimentation prior to disinfection to remove turbidity, suspended solids, and colloidal materials from the water.

- Disinfection: Once the water has been pre-treated and purified, a disinfectant such as chlorine, hypochlorite, ozone, UV radiation, etc. is usually added to kill or remove pathogens from the water.

The choice of disinfection depends on the use and quality standards of the water. Different methods of disinfection have different advantages and limitations. For example, chlorine is a widely used disinfectant, but it may produce by-products that affect water quality. Ultraviolet disinfection is effective in killing bacteria and viruses, but it does not provide long-lasting disinfection. Therefore, water treatment plants choose the appropriate disinfection method based on specific requirements and water quality conditions.

Common Disinfection Methods in Water Treatment

Disinfection in water treatment is a critical step in ensuring that water is safe for human consumption by killing or inactivating harmful microorganisms such as bacteria, viruses and parasites. Disinfection usually follows primary treatment (e.g., sedimentation) and secondary treatment (e.g., filtration). There are several common methods of disinfection in water treatment:

Chlorine disinfection

Chlorine gas or chlorine compounds (e.g., sodium hypochlorite) are added to water to kill bacteria, viruses, and other pathogens. Chlorine is an effective and widely used disinfectant that can be used in either gas form or as a liquid solution. Chlorine is usually delivered as a gas. Gaseous chlorine can be introduced into a water treatment process through a gas chlorine cartridge or a gas chlorine generator. Gaseous chlorine dissolves in water and reacts with microorganisms in the water. Hypochlorous acid is usually delivered as a liquid. It can be injected into the water through a piping system or a pump(can be delivered by H Solenoid Dosing Pump) to sanitize the liquid hypochlorite.

Ozone sterilisation

Ozone (O3) is a powerful oxidizing agent used to disinfect water. It is particularly effective in removing taste and odor substances as well as in inactivating microorganisms. Ozone is produced on site by an ozone generator and then injected into the water. Ozone is usually delivered as a gas. The ozone gas is then introduced into the water through an injection system or ozone generator to disinfect and oxidize organic matter.

Ultraviolet (UV) disinfection

Using UV light to disinfect water prevents microorganisms from reproducing by damaging their DNA. UV disinfection does not require chemicals and is effective against a wide range of pathogens. UV disinfection systems include UV lamps, which kill microorganisms through UV radiation. Water flows through these lamps and the UV light is able to kill microorganisms directly in the water without the need for any chemical medium.

Chlorine dioxide (CO2)

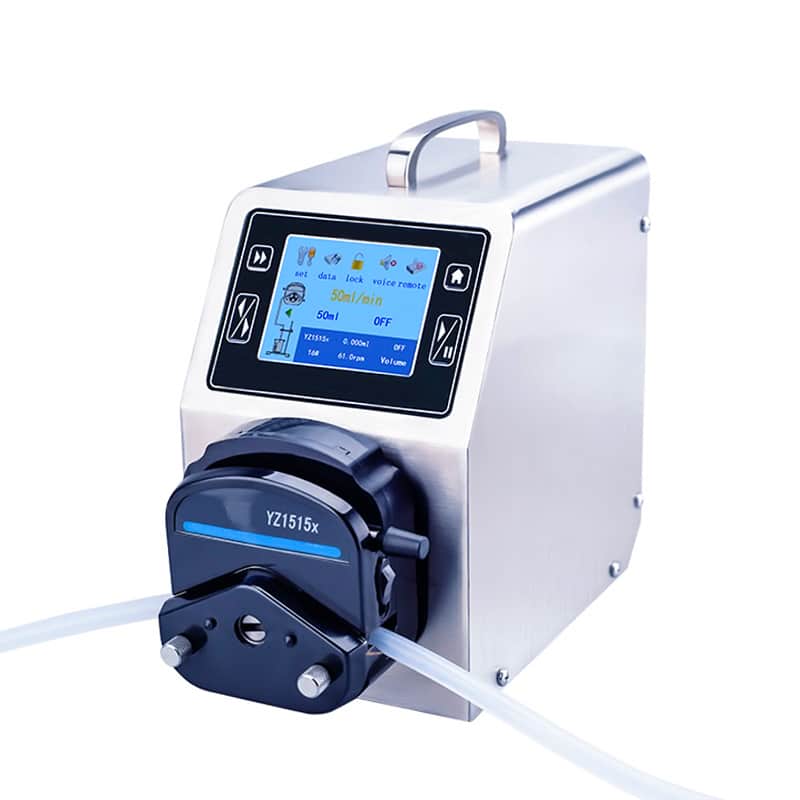

Chlorine dioxide (ClO2) is an effective disinfectant used in some water treatment plants. It is particularly helpful in controlling tastes and odors, as well as inactivating some microorganisms. Liquid chlorine dioxide is stored as a liquid, usually in rubber or plastic containers, and then delivered to the water treatment process through an injection system or pump(HJ-Z Mechanical Dosing Pump). This can be accomplished through liquid chlorine pumps, peristaltic pumps, and other delivery devices.

Chloramine sterilization

Chloramine is a combination of chlorine and ammonia used as a disinfectant in some water treatment systems. It provides longer lasting residual disinfection than free chlorine. Chloramines are usually delivered in liquid form and are composed primarily of a compound of chlorine and ammonia. Liquid chloramines can be prepared by mixing chlorine and ammonia and then dissolving in water to form. This mixture can be added to the water through a pump or injection system.

Oxygen-based disinfection

Oxidizing disinfectants such as peroxides, peracetic acid and hydrogen peroxide can be used to kill microorganisms and remove certain organisms from water. It is usually delivered in liquid form.

When pumping disinfectants in water treatment, dosing metering pumps are often one of the most suitable choices, especially when precise control of the disinfectant dosage is required. Below is a table for dividing different disinfectants into combinations with the corresponding metering pump materials:

| Disinfectant | Metering Pump Material |

| Chlorine Gas (Cl2) | Copper alloys, stainless steel, plastics, etc. |

| Sodium Hypochlorite (NaClO) | Stainless steel, plastics, etc. |

| Chlorine Dioxide (ClO2) | Stainless steel, corrosion-resistant materials, etc. |

| Chloramine | Stainless steel, plastics, corrosion-resistant materials, etc. |

| Hydrogen Peroxide (H2O2) | Corrosion-resistant materials, specially designed pumps |

It is important to note that the disinfection process should be carefully monitored to ensure that the correct dose of disinfectant is applied and that the water is safe for drinking while minimizing the generation of harmful disinfection by-products (DBPs), which can be a concern in some cases. Water treatment facilities continually monitor and adjust the disinfection process to meet safety and quality standards.

The role of disinfection in water treatment

The role of disinfection in water treatment is very important, mainly to ensure the safety and hygiene of drinking or industrial water. The following are the main roles of disinfection in water treatment:

- Killing pathogens: The disinfection process effectively kills or removes a wide range of pathogens, including bacteria, viruses, parasites and other microorganisms from water. This helps prevent waterborne diseases such as cholera, malaria, and intestinal infections.

- Protects public health: by killing pathogens, disinfection protects people from waterborne pathogens, thereby maintaining public health and preventing outbreaks.

- Eliminate odors and tastes: some water sources may contain undesirable odors and tastes, and disinfection can help remove or reduce these odors and tastes, making the water more palatable and drinkable.

- Extend the storage life of water: disinfection extends the life of drinking water during storage and distribution and reduces the growth of microorganisms in the water, thus ensuring that drinking water remains safe until it is delivered to users.

- Prevents pipeline contamination: Water may travel through pipelines for long periods of time before it is delivered to users, and disinfection helps prevent microbial contamination within the pipeline, ensuring that users have access to a safe water source.

- Meets legal requirements: In most countries, drinking water is required by law to be properly disinfected to ensure that it meets hygiene standards.

Advanced disinfection technology

Although traditional disinfection methods, such as chlorination and ultraviolet treatment, are widely used, advances in technology have led to the development of more sophisticated disinfection techniques. The following are some examples:

- Advanced Oxidation Processes (AOPs): AOPs involve the use of strong oxidizing agents, such as ozone and hydrogen peroxide, in combination with ultraviolet light or other catalysts. These processes are effective in removing persistent organic compounds and pathogens from water.AOPs are particularly valuable in treating wastewater and groundwater contamination.

- Electrochlorination: This innovative method generates chlorine gas by passing an electric current through a brine solution. Electrochlorination is a sustainable and efficient way to generate chlorine gas without the need to handle and transport chlorine gas or liquid chlorine.

Summary

Disinfection in water treatment is a critical step in ensuring that the water we use is safe and free from harmful microorganisms. Advances in technology and a better understanding of the challenges associated with disinfection are helping to improve the efficiency, safety and sustainability of water treatment processes.

Besides metering pumps, HAOSH also offers Pump Accessories, Mixer Agitator and Dosing System, please feel free to contact us.