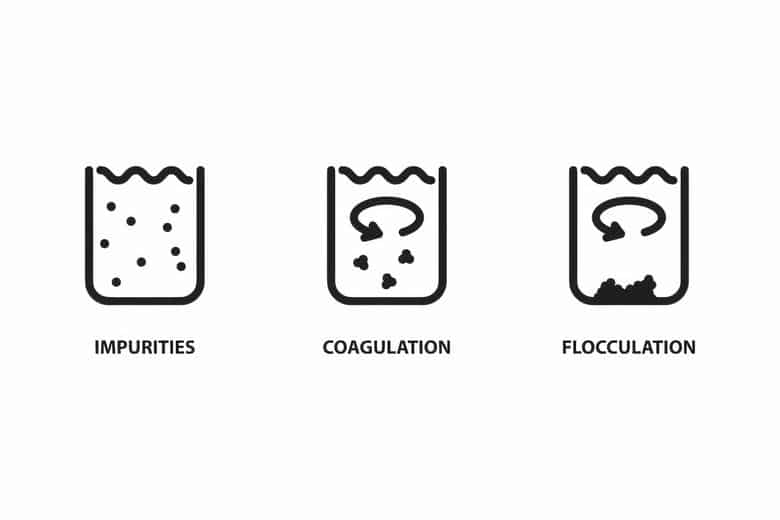

Coagulation and Flocculation

Coagulation and flocculation are the two processes used in water treatment to remove suspended particles from water. Coagulation is the process of destabilizing particles so they can clump together, while flocculation is the process of causing particles to clump together to form larger particles that can be more easily removed from water, making it safe for drinking, swimming and other uses.

Coagulation

In water treatment, coagulation is used to remove suspended particles, such as dirt, sediment, bacteria and viruses. Coagulation is the process of destabilizing colloidal particles, where the coagulant reacts with water molecules to form a positive charge around the particles. This positive charge neutralizes the negative charge on the particles, thereby reducing the zeta potential. When the zeta potential reaches zero, the particles no longer repel each other and they can clump together, forming larger particles (flocs) that can be more easily removed from the liquid.

The amount of coagulant that needs to be added to the water to achieve zero zeta potential will depend on the type of coagulant and the pH of the water. The optimum amount of coagulant will vary depending on specific water quality parameters. It is best to consult with a water treatment specialist to determine the optimum amount of coagulant for a particular water treatment application.

Common coagulants

Coagulants are usually metallic salts, such as aluminum sulfate or ferric chloride. The range of coagulant parameters depends on the type of coagulant.Commonly used coagulants: aluminum sulfate, ferric chloride and polyelectrolyte are all chemicals used in water treatment.

Three common coagulants in water treatment

- Aluminum sulfate is used to treat surface water. It is a white powder that is dissolved in water before being added to the treatment system. Aluminum sulfate works by reacting with negatively charged particles in the water, which helps to clump them together and form larger particles. These larger particles can then be easily removed from the water by precipitation or filtration.

- Ferric chloride is also used to treat surface water. It is a clear liquid that can be added directly to the treatment system. Ferric chloride acts similarly to aluminum sulfate, reacting with negatively charged particles in the water to form larger particles.

- Polyelectrolytes are often used in combination with aluminum sulfate or ferric chloride. Polyelectrolytes are long chain molecules with a positive charge. When they are added to water, they attach to the negatively charged particles in the water. This helps to clump the particles together and form larger particles that can then be easily removed from the water.

Other seven additional coagulants

- Hydrated lime: Hydrated lime is a base that reacts with acids in water to form a precipitate. This precipitate can then be removed by sedimentation or filtration. Hydrated lime is used to treat water for a variety of purposes, including: removing color and turbidity, reducing hardness, neutralizing acidity and controlling corrosion.

- Magnesium carbonate: Magnesium carbonate is another base that reacts with acids in water to form a precipitate. This precipitate can then be removed by sedimentation or filtration. Magnesium carbonate is used to treat water for a variety of purposes, including: removing color and turbidity, reducing hardness and neutralizing acidity.

- Organic coagulants: Organic coagulants are made from natural sources, such as seaweed or wood. They react with the negatively charged particles in water to form larger particles. These larger particles can then be easily removed from the water by sedimentation or filtration. Organic coagulants are used to treat water for a variety of purposes, including: removing color and turbidity, reducing algae growth and removing heavy metals.

- Flocculants: Flocculants are a type of chemical that is used to aid in the removal of suspended particles from water. Flocculants work by binding to the particles and causing them to clump together. This makes it easier for the particles to be removed from the water by sedimentation or filtration. Flocculants are often used in conjunction with coagulants.

- Polymer flocculants: Polymer flocculants are a type of flocculant that is made from long chains of molecules. Polymer flocculants are often used in conjunction with other flocculants, such as alum or ferric chloride. Polymer flocculants work by forming a network around the particles, which helps to clump the particles together and form larger particles.

- Coagulation aids: Coagulation aids are chemicals that are used to improve the effectiveness of coagulants. Coagulation aids work by increasing the surface area of the coagulant particles, which makes it easier for them to react with the negatively charged particles in the water.

The right dose and the right ph range

| Coagulant | Dosage Range (mg/L) | Optimum pH Range |

| Aluminum sulfate | 1-5 | 5.5-6.5 |

| Ferric chloride | 1-5 | 5.0-6.0 |

| Polyelectrolytes | 0.1-1 | 6.0-7.0 |

| Hydrated lime | 1-5 | 10.0-11.0 |

| Magnesium carbonate | 1-5 | 8.0-9.0 |

| Organic coagulants | 0.1-1 | 5.0-6.0 |

| Flocculants | 0.1-1 | 6.0-7.0 |

| Polymer flocculants | 0.1-1 | 6.0-7.0 |

| Coagulation aids | 0.1-1 | 6.0-7.0 |

The effect of improper use of coagulants

- Coagulant dosage: The amount of coagulant added to the water affects the size and stability of the flocs. Too much coagulant will result in large and heavy flocs settling too quickly, while too little coagulant will result in small and weak flocs that are difficult to remove.

- PH: The pH of the water will affect the effectiveness of the coagulant. The optimum pH for coagulation will vary depending on the type of coagulant used.

- Temperature: The temperature of the water will affect the reaction rate of the coagulant. Higher temperatures will result in faster reaction rates, while lower temperatures will result in slower reaction rates.

Media for transporting coagulants

By taking these factors into account, you can choose the pump that provides the performance and reliability needed to safely and effectively use chemicals to treat water:

- Diaphragm pumps: Diaphragm pumps are positive displacement pumps that are capable of handling high viscosity fluids. They are also relatively accurate and can be used in a variety of applications.

- Hydraulic dosing pumps: Hydraulic dosing pumps use a hydraulic fluid to actuate the pump’s diaphragm. Hydraulic dosing pumps are typically more accurate than mechanical dosing pumps, and they can handle higher pressures and flow rates. However, they are also more expensive and complex.

- Motor-driven metering pumps: Motor-driven metering pumps are powered by an electric motor that turns a gear train. This gear train moves a piston or diaphragm, which in turn moves the fluid being pumped. Motor-driven metering pumps are typically less expensive than other types of pumps, but they are not as accurate and cannot handle as high flow rates.

- Piston pumps: Piston pumps are also positive displacement pumps that are capable of handling high viscosity fluids. They are typically more expensive than diaphragm pumps, but they can provide higher accuracy and flow rates.

- Mechanical dosing pumps: Mechanical dosing pumps are powered by a mechanical actuator, such as a screw or piston. Mechanical dosing pumps are less expensive than electromagnetic dosing pumps, but they are not as accurate and cannot handle as high flow rates. Mechanical dosing pumps are a good choice for applications where accuracy is not as critical, such as in the wastewater treatment industry.

The 10 coagulants listed above are used in pumps in a variety of materials, including:

- Plastic: Plastic is a common material for pumps used to transport coagulants. It is resistant to corrosion and is relatively inexpensive. HAOSH’s H Solenoid Dosing Pump is an excellent choice.

- Steel: Steel is a more durable material than plastic, but it is also more expensive. Steel pumps are often used in applications where the coagulants are corrosive or where the pump is exposed to high temperatures.

- Bronze: Bronze is a corrosion-resistant material that is often used in pumps that transport coagulants. It is more expensive than plastic, but it is also more durable.

HAOSH has a wide range of pumps to choose from, HJ-Z Mechanical Dosing Pump can convey the above 10 chemicals with high efficiency.

Flocculation

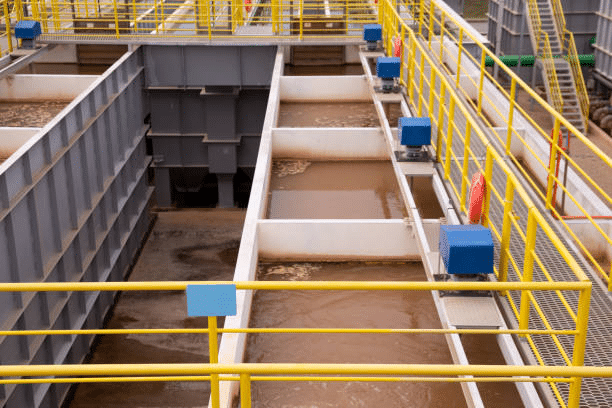

Flocculation is the second step and flocculants are negatively charged chemicals. When they are added to the water, they adhere to the flocs. This helps stabilize the flocs and makes them easier to remove from the water. The flocculation process is typically carried out in a tank called a flocculator. The flocculator is designed to provide gentle mixing of the water, which helps to promote the formation of flocs. The flocs are then allowed to settle out of the water, and the clear water is drawn off from the top of the flocculator.

Eight common flocculants

- Alum: Alum is a type of flocculant that is made up of aluminum and sulfate. It has a positive charge, which helps it to attach to negatively charged particles in water. This causes the particles to clump together and form larger particles, which can then be easily removed from the water.

- Magnesium chloride: Magnesium chloride is a type of flocculant that is made up of magnesium and chloride. It has a positive charge, which helps it to attach to negatively charged particles in water. This causes the particles to clump together and form larger particles, which can then be easily removed from the water.

- Sodium aluminate: Sodium aluminate is a type of flocculant that is made up of aluminum and sodium. It has a positive charge, which helps it to attach to negatively charged particles in water. This causes the particles to clump together and form larger particles, which can then be easily removed from the water.

- Polyacrylamide: Polyacrylamide is a type of polymer that is used as a flocculant. It is a long chain of molecules with a negative charge. This negative charge helps it to attach to positively charged particles in water, causing them to clump together and form larger particles that can be easily removed.

- Chitosan: Chitosan is a natural polymer that is used as a flocculant. It is made from chitin, which is a substance found in the shells of crustaceans. Chitosan has a positive charge, which helps it to attach to negatively charged particles in water, causing them to clump together and form larger particles that can be easily removed.

- Flocculant aids: Flocculation aids are chemicals that are added to water to improve the effectiveness of flocculants. They do this by increasing the surface area of the flocculants, which makes them more effective at attaching to particles in water.

- Coagulation aids: Coagulation aids are chemicals that are added to water to improve the effectiveness of coagulants. They do this by increasing the charge of the coagulants, which makes them more effective at attracting particles in water.

- Natural flocculants: Natural flocculants are made from plant or animal sources. They are often used in small-scale water treatment systems because they are less expensive than synthetic flocculants.

The right dose and the right ph range

| Flocculation | Dosage Range (mg/L) | pH Range |

| Alum | 10-100 | 5-9 |

| Magnesium chloride | 5-50 | 6-9 |

| Sodium aluminate | 5-50 | 6-9 |

| Polyacrylamide | 0.1-1 | 5-9 |

| Chitosan | 0.1-1 | 5-9 |

| Flocculation aids | 0.1-1 | 5-9 |

| Coagulation aids | 0.1-1 | 5-9 |

| Natural flocculants | 0.1-1 | 5-9 |

The effect of improper use of flocculants

The effects of using a flocculant improperly can vary depending on the specific flocculant and the application. However, some potential effects of improper use include:

- Ineffective treatment: If the flocculant is not used at the correct dosage or pH, it may not be effective in removing impurities from water. This can lead to water that is not safe to drink or use for other purposes.

- Residual chemicals: If the flocculant is not properly rinsed from the water, it can leave behind residual chemicals. These chemicals can be harmful if ingested or absorbed through the skin.

Media for transporting flocculants

The type of pump most suitable for transporting flocculants depends on the specific application. For example, centrifugal pumps are commonly used in water treatment plants to transfer flocculants, while diaphragm pumps are commonly used in chemical processing plants to transfer flocculants. It is important to note that flocculants can be corrosive, so it is important to choose a pump made of corrosion-resistant materials. It is also important to select a pump that can operate at the correct flow rate and pressure to ensure uniform distribution of flocculant in the water. HAOSH’s HS Solenoid Dosing Pump is a new generation of electromagnetic diaphragm pumps.

What are the problems encountered in coagulation and flocculation?

- Incomplete coagulation: If the coagulant is not added in the correct dose or at the correct pH, it may not be effective in destabilising the colloidal particles. This can lead to incomplete removal of impurities from the water.

- Ineffective flocculation: If the flocculant is not added in the correct dose or at the correct pH, it may not be effective in forming larger flocs. This can lead to flocs that are too small to be easily removed from the water.

- Flocs breaking up: Flocs can break up if they are not agitated properly. This can lead to impurities being released back into the water.

- Residual chemicals: If the coagulant or flocculant is not properly rinsed from the water, it can leave behind residual chemicals. These chemicals can be harmful if ingested or absorbed through the skin.

- Environmental impact: Some coagulants and flocculants can have a negative impact on the environment. For example, some coagulants can contribute to the formation of harmful algae blooms.

Solution

- Monitoring the coagulation and flocculation process: The coagulation and flocculation process should be monitored to ensure that it is effective. This can be done by measuring the turbidity of the water, the size of the flocs, and the concentration of residual chemicals.

- Using the correct dosage of coagulant and flocculant: The correct dosage of coagulant and flocculant should be used to ensure that the process is effective. This can be determined by conducting jar tests.

- Agitating the water properly: The water should be agitated properly to prevent flocs from breaking up. This can be done by using a mechanical stirrer or a dissolved air flotation (DAF) system. HAOSH’s Tank Agitator Mixer is best suited for mixing these chemicals.

- Rinsing the water properly: The water should be rinsed properly to remove any residual coagulant or flocculant. This can be done by using a filter or a clarifier.

- Using environmentally friendly coagulants and flocculants: Environmentally friendly coagulants and flocculants should be used to minimize the negative impact on the environment.

Summary

Overall, coagulation and flocculation are an important and effective water treatment process. They can help improve the quality, safety and efficiency of water treatment. HAOSH is the world’s leading brand of fluid control equipment, specializing in the development of dosing and metering pumps and systems, providing perfect technology and service. We are dedicated to the production, design assembly and sales of water treatment equipment, and we want to bring you better products and services, please feel free to contact us.