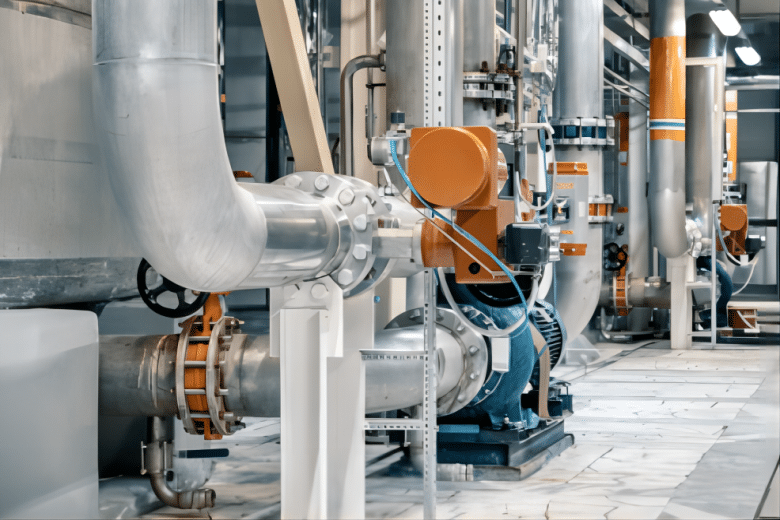

Hydraulic Dosing Pump

HAOSH hydraulic diaphragm dosing pumps combine the advantages of both piston and diaphragm dosing pumps with a hydraulically driven configuration that makes it easy to achieve the high pressure dosing required.

Hydraulic diaphragm metering pumps are particularly suitable for applications where corrosive, toxic and flammable liquids are dosed at very high pressures and extreme temperatures. For example, in the petrochemical industry, refineries and oil and gas production, or as special metering pumps in the process industry.

how does a Hydraulic diaphragm metering pump work?

- Hydraulic diaphragm type metering pump hydraulic system, its structure consists of plunger, cylinder, cylinder cover, import and export valves, hydraulic diaphragm type and three valves (i.e.: bleed overload valve, limit valve, compensation valve). In the work of the diaphragm separates the hydraulic oil and media, so the hydraulic diaphragm type metering pump has the advantage of no leakage.

- Hydraulic diaphragm metering pump hydraulic end of the plunger is driven by the reciprocating motion of the crank linkage mechanism at the transmission end of the work. Plunger in the hydraulic cavity for reciprocating motion, prompting the hydraulic oil pressure changes, so that the hydraulic diaphragm type flexural displacement to transport the medium, the relative stability of the hydraulic oil volume in the hydraulic cavity, the function of the three valves to maintain.

- Overload valve automatically discharges the gas in the hydraulic oil into the hydraulic cavity to ensure smooth work, to avoid excessive hydraulic oil or discharge pipeline obstruction to generate overpressure automatically open the overload valve to achieve the purpose of protection.

- The limit compensation device is to push the opening of the limit valve with the help of hydraulic diaphragm type, replenish the oil volume at any time according to the vacuum in the hydraulic cavity, and ensure the hydraulic oil in the hydraulic cavity is full.

Industry applications

HAOSH’s hydraulic dosing pumps feature a rugged design that ensures reliable operation even under the most demanding conditions.

- Water and wastewater treatment —— Water and wastewater must be treated efficiently and economically within appropriate quality standards. HAOSH pumps are not only effective and safe in transporting a wide range of chemical additives, but are also known for their reliability. Long-term cost benefits are brought about by preventive maintenance.

- Chemical and petrochemical processing —— The pumps’ durable design allows them to effectively withstand the toxicity of process fluids, while their flow control capabilities can withstand temperature and pressure changes during production.

- Oil and gas production —— The pump is ideal for onshore oil and gas production because it can continuously inject methanol, corrosion inhibitors, oxygen binders and other corrosive materials in the harshest conditions in the most remote areas.