Polymer Preparation Unit

Polymer preparation units are automated systems for the preparation of liquid or powdered polymers, designed for the fully automated dosing of polymer solutions.

The polymer dosing system can be used to batch flocculation aids for the preparation of ready-to-use polymer solutions. The design is optimized to ensure that the polymer maturation process is completed with minimal footprint.

Polymer preparation units are automated systems for the preparation of liquid or powdered polymers, designed for the fully automated dosing of polymer solutions.

The polymer dosing system can be used to batch flocculation aids for the preparation of ready-to-use polymer solutions. The design is optimized to ensure that the polymer maturation process is completed with minimal footprint.

How the polymer preparation unit works?

One of the most important steps in the conventional wastewater treatment process is the treatment of suspended solids and colloidal particles in the water, usually achieved in the primary or physicochemical treatment of the treatment plant.

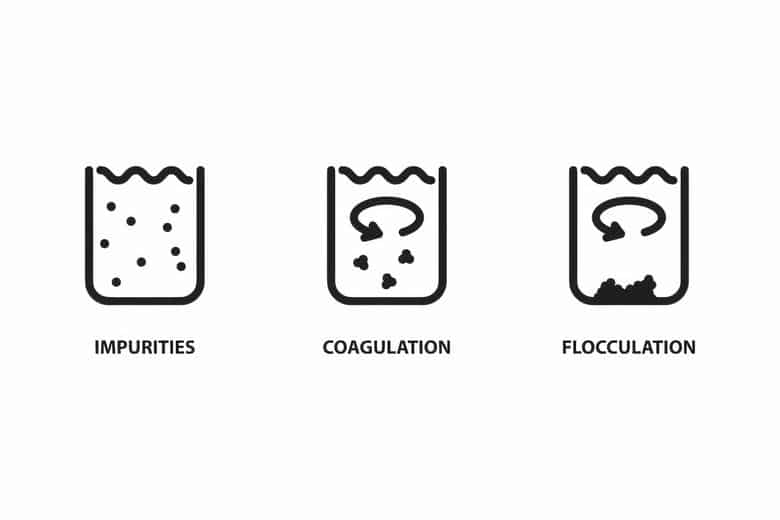

The purpose of the physicochemical treatment of the polymer preparation unit, which consists of a coagulation phase, a flocculation phase and a final decantation, is to change the physical state of these substances by adding chemical products to convert them into particles that can be separated by sedimentation in two steps.

In the first step, coagulation destabilizes the colloids by neutralizing their loading, resulting in the formation of particles of larger size. Later, during the flocculation process, the colloidal particles fuse into flocs and increase in size and weight, thus achieving decantation.

In the second step, flocculation, the aim is to unify the formed flocs into large particles, which settle faster. For this purpose, flocculants are introduced and the water to be treated is stirred very slowly to ensure that the reagents are well mixed and at the same time that the flocs formed do not break up. Most commonly used are polyelectrolytes.

Applications

- Water treatment: flocculation of industrial water and drinking water

- Wastewater treatment: physical and chemical treatment

- Sludge treatment: centrifuges, filter presses to improve dewatering

- Paper industry: retention aid

- Various other industries: chemical, petrochemical, quarry, etc.

- Fully automatic operation, saving labor.

- Adjustable dosage of pharmaceuticals to ensure the treatment effect and avoid waste.

- All stainless steel box, reliable quality, good corrosion resistance.

- Simple maintenance, beautiful appearance.

- No need for base seat and fixing.

- All information is contact type output.

- The mixer is flexible to adjust the running time to ensure the effect and save energy.

- Running process with airlift and overflow protection.