Metering Pump vs Dosing Pump

Metering Pump vs Dosing Pump

What is a metering pump?

A metering pump is a pump used to accurately dose and deliver liquids or chemicals. Its primary function is to accurately deliver a liquid to a target location based on a predetermined dosage or flow rate. Metering pumps usually have adjustable flow controls that allow the output flow rate to be precisely adjusted as needed.

Features

- Precise metering

- Adjustable flow rate

- Multiple operating principles

- Wide range of applications

What is a dosing pump?

A dosing pump is a pump used to accurately add chemicals or other additives to a fluid system, with an adjustable flow control device that allows for precise adjustment of the amount of chemicals to be delivered as needed. This ensures that the concentration and dosage of the chemical is within a specific range to meet the requirements of the treatment process and to guarantee optimal treatment results. Dosing pumps are usually made of high-quality materials and advanced technology to ensure their stable and reliable performance, and at the same time, they can adapt to different working environments and requirements. For example, pH adjustment, disinfectant delivery, and control of chemical reactions in water treatment.

Features

- Precise dosing

- Adjustable flow rate

- Stable and reliable

- Automatic control

- Variety of options

- Corrosion resistance

Difference between metering & dosing pumps

| Pump | Metering Pump | Dosing Pump |

| Use | Used where precise control of flow rate and delivery dose is required | Mainly used for dosing and liquid transportation |

| Control Mode | Often controlled by dosing controllers or PLCs | Can be controlled manually or automatically |

| Precision | High precision | High precision |

| Dosing Method | Continuous dosing, intermittent dosing | Intermittent and quantitative dosing can be realized |

| Advantages | Precise control of flow rate and dosage, high stability | Different dosing methods and flexible control can be realized |

| Disadvantages | Higher price | Slightly lower accuracy than metering pumps |

| Flow Range | Milliliter/hour class | Milliliters/hour to liters/hour |

| Applicable Flow Rate | High precision, low flow rate | Wide range |

Dosing pumps / dosing pumps application industry

Dosing/metering pumps are used in various industries such as pharmaceuticals, food industry, water treatment industry and many more.

In each of these industries, there is a need for a system that can inject measured quantities of substances into the fluid stream, and dosing/metering pumps fulfill this need perfectly.

The choice of different dosing/metering pumps depends on:

- The fluid being injected

- The level of accuracy required

- The flow pressure

Types of Metering/Dosing Pumps

Metering Pump

Piston/plunger metering pumps

A piston/plunger metering pump consists of a housing in which a plunger or piston is placed. As the piston reciprocates within the housing, fluid is drawn into the chamber during the suction stroke and then pushed out during the discharge stroke. The volume of the chamber and the position of the piston allow us to know precisely the amount of fluid being metered into the fluid stream.This system makes piston/plunger metering pumps the most accurate of the different metering pumps for metering fluid. Chemical feed pumps, for example, inject precise amounts of chemicals into process streams.

Peristaltic metering pump

Using the peristaltic principle, through the compression and relaxation of the pipeline to promote the flow of liquid, applicable to the need for accurate measurement of the occasion.

Diaphragm Metering Pump

Diaphragm metering pump is a pump that uses a diaphragm to transfer liquid. A diaphragm is a membrane made of flexible material that is located between two chambers of the pump. As the pump operates, the diaphragm moves up and down, pressing liquid from one chamber into the other. It uses a flexible diaphragm instead of a piston to change the volume of the pump chamber, thereby increasing and decreasing the pressure of the fluid inside. So it is suitable for liquid transporting flocs.

Pulse metering pump

Pulse metering pump realizes metering and conveying by controlling the frequency and width of pulse wave, which is suitable for occasions requiring fast metering.

Dosing Pump

Mechanical Dosing pump

Mechanical dosing pumps are commonly used in dosing pumps and are a common type of dosing pump. Mechanical diaphragm pumps move diaphragms back and forth by mechanical actuation for fluid intake and discharge. They are also subject to different levels of wear than piston pumps , mechanical diaphragms are also subject to pulse discharges and other effects. However, this can be mitigated by having two diaphragm settings. Another advantage of mechanical dosing is that their construction makes them hermetically sealed, making them the best choice for toxic fluids.

hydraulic Dosing pump

A hydraulic dosing pump is a dosing pump that uses hydraulic power to drive the dosing mechanism. It controls the flow of dosing liquid by utilizing hydraulic pressure to move a diaphragm or plunger. Hydraulic dosing pumps are widely used in a variety of industries and applications where precise dosing of chemicals or additives is required. One of the advantages of hydraulic dosing pumps is that they can handle a wide range of flow rates and pressures, making them flexible for a variety of dosing needs. HY-ZR series hydraulic dosing pump is an integrated pump that provides precise dosing performance with minimum maintenance. It is integrated with a safety valve to prevent overload pressure.

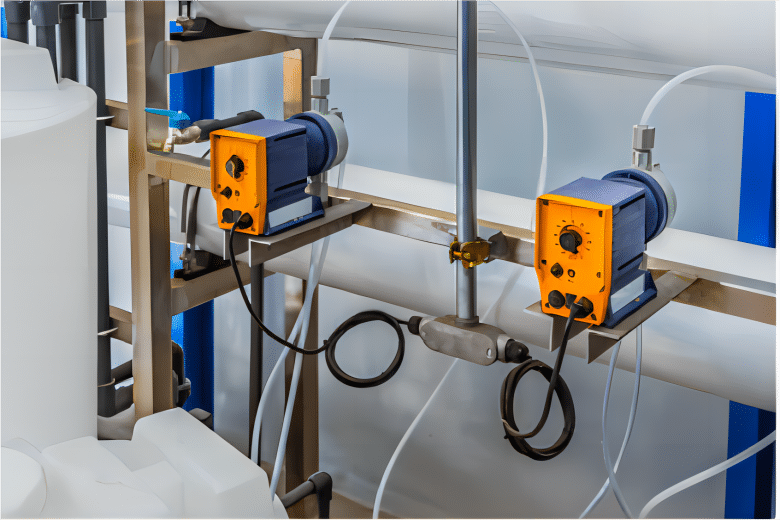

Solenoid Dosing Pump

Solenoid dosing pumps are a special type of dosing pumps that use solenoid valves to control the flow of liquids for precise metering and dosing by means of an electromagnetically driven piston or diaphragm. It can be widely used in industry, water treatment, medical and laboratory fields. It is often used where high precision and stable flow control is required, and can be used in automated systems for precise dosing according to a predetermined program. HAOSH solenoidal dosing pumps are an excellent choice.

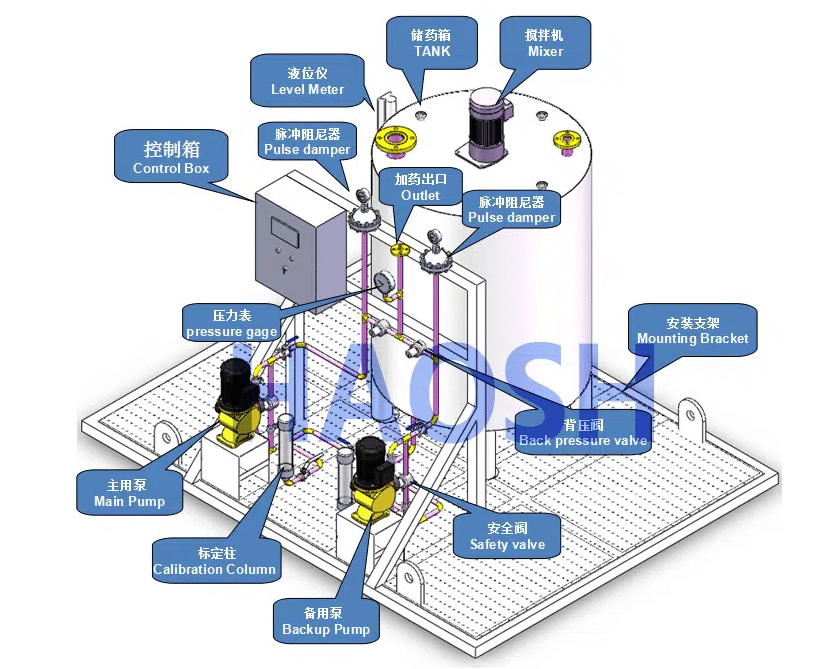

The best choice for dosing systems

Dosing systems are paired with either a dosing pump or a metering pump depending on the specific needs of the application. Dosing pumps are pumps that add chemicals or other liquids to another fluid. Dosing pumps are typically used in applications that require precise flow rate control, such as water treatment and pharmaceuticals. Metering pumps are pumps that precisely add liquid to another fluid. Metering pumps are typically used in applications that require precise control of the concentration of additives, such as oil and gas.

Selection Considerations

- The flow rate that needs to be precisely controlled

- The type of liquid to be treated

- Volume of liquid to be added

- The cost of the pump

How to maintain the pump

- Clean regularly

- Check lines and seals

- Replace parts regularly

- Calibrate flow rate

- Keep it dry

- Adjust the controller

Summary

If you don’t know how to choose a pump, please contact our team to provide you with a solution.HAOSH, as a leading brand of global fluid control equipment, specializes in the development of dosing metering pump and systems, and also provides equipment such as mixing agitators, accessories and pulsation dampers.