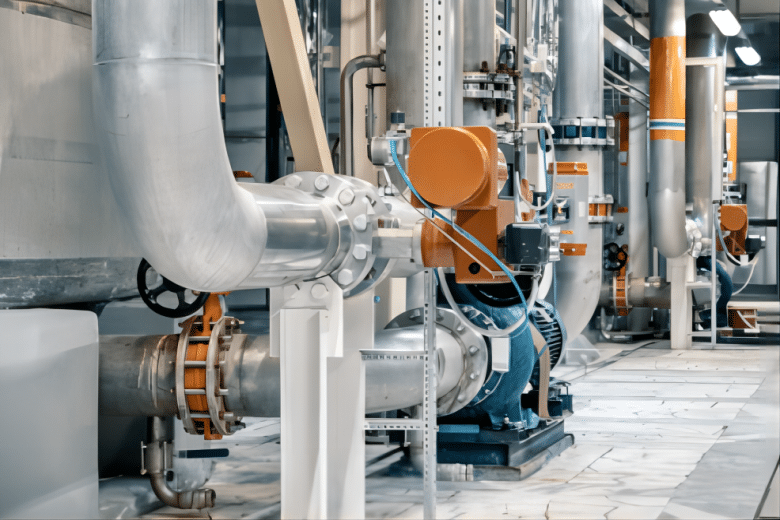

Dosing Metering Pump

HAOSH dosing metering pumps are reciprocating positive displacement pumps that provide the highest possible metering accuracy. Ensuring minimal chemical consumption but optimal disinfection. The interface integrates the pump into an automated process.

Each metering pump manufactured by HAOSH offers special advantages: high energy efficiency, low maintenance costs and very long diaphragm life. All types of needs can be met in industries such as water and wastewater treatment, oil and gas, chemical, pharmaceutical and biotechnology, food and beverage.

What Is A Chemical Metering Pump?

Metering pump, also known as dosing pump, quantitative pump or proportional pump, is a positive displacement chemical metering device capable of changing the volume manually or automatically according to the needs of the process. It is mainly used for precise injection of chemicals, such as acids, bases, corrosive or viscous liquids. Common demand occasions are as follows:

- Requires precise metering of fluids

- Low flow rates in ml/hr or GPH are required

- Flow rates vary and are controlled by a computer, microprocessor, DCS or PLC

- Handles corrosive, hazardous or high temperature fluids

- Need to pump viscous fluids or slurries

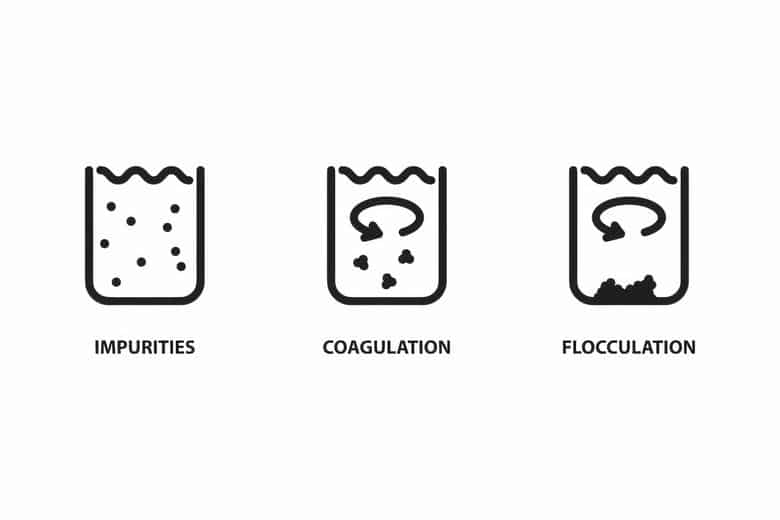

how does a Chemical dosing pump work?

The motor of the pump drives the worm through the coupling and makes the main shaft and eccentric wheel to make rotary motion by decelerating the worm gear, and the eccentric wheel drives the sliding adjustment seat of the bow-type connecting rod to make reciprocating motion. When the plunger moves to the back dead point, the pump cavity gradually forms a vacuum, the suction valve opens and the liquid is sucked in; when the plunger moves to the front dead point, the suction valve closes and the discharge valve opens, the liquid is discharged when the plunger moves further.

In the pump’s reciprocal cycle of work to form a continuous pressure, quantitative discharge of liquid. At the same time to complete the transport, measurement and regulation of the function.

Types of metering pumps

There is a wide range of dosing pumps with a wide range of capacities. From a few milliliters (for laboratory use) to 35,000 liters per hour (for industrial engineering).

Depending on the overflow section:

- Diaphragm metering pumps

- Hydraulic diaphragm metering pumps

- Plunger metering pumps

- Peristaltic pumps

Classification by pump drive:

- Electromagnetic driven metering pumps

- Motor-driven metering pumps

According to the working mode:

- Reciprocating type

- Rotary type

- Gear type