Chloramines In Water Treatment

In the water treatment industry, sterilization and disinfection a key and indispensable parts of the most representative means of disinfection through the chloramine metering pump to add chloramine-containing reagents, which has been widely used in the water treatment industry in various types of disinfection equipment.

What chloramines?

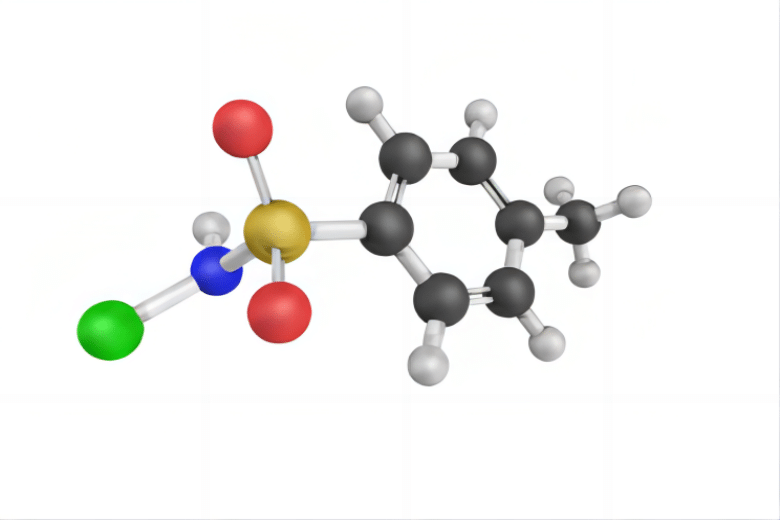

Chloramine is a nitrogen-containing compound usually a collective term for a class of chloramine compounds. Chloramine compounds usually contain chlorine and nitrogen atoms, and they are chemically available in various structures and types, including single chloramines, dichloramines, and trichloramines. These compounds are commonly used as disinfectants and bleaching agents. Chloramine is also an effective deoxidizer, scale inhibitor and corrosion inhibitor, so it is widely used in boiler water chemical treatment.

Chloramine compounds disinfect water, purification tanks, swimming pools, and water supply systems to kill bacteria, viruses, and other microorganisms. Chloramines are also used to bleach paper, fabrics, and other materials. Different types of chloramine compounds have different strengths and applications, and their use should be done with caution, as overuse may produce harmful substances.

Properties Of Chloramines

Chloramine compounds have many different properties depending on their type and structure.

- Disinfectant: Chloramine compounds usually have strong disinfectant properties, killing bacteria, viruses, and other microorganisms. They are very useful in water treatment disinfection, swimming pool disinfection, and sanitation.

- Bleaching: Chloramine compounds can be used as bleaching agents for paper, fabrics, and other materials. They remove color and bleaching substances, making items whiter.

- Strong oxidizing properties: Chloramine compounds are strong oxidizing agents that can react with organic matter, thus removing organic pollutants in water.

- Decomposition temperature: Different types of chloramine compounds have different decomposition temperatures, which means they may decompose or become inactive under different conditions.

- Odor: Some chloramine compounds may produce a pungent odor, which may be considered unsuitable in some applications.

Effectiveness of chloramines as a disinfectant

Its effectiveness in disinfection depends on a number of factors, including the type of chloramine, its concentration, the contact time, the water conditions, and the type of microorganisms in the water being treated. The correct use of chloramines is very important because too high a concentration may be harmful to human health, while too low a concentration may not be effective enough to kill microorganisms. In addition, different types of chloramines (e.g., Chloramine T, Chloramine B, Chloramine D, etc.) may differ in their disinfection effectiveness, so it is also critical to select the appropriate type of chloramine.

Role of Chloramines In Water Treatment

Chloramines in water treatment

It can be used in drinking water treatment, swimming pool disinfection, industrial water treatment, wastewater treatment, cooling water treatment, and pond and lake management to ensure hygienic and safe water quality. It helps to kill bacteria, viruses, and microorganisms, purify water sources, and maintain clean and healthy water bodies.

Disinfection Of Chloramines In Water Treatment

Its disinfecting action is achieved by releasing chlorine ions that kill bacteria, viruses, and other microorganisms, thereby purifying the water supply. The disinfecting effect of chloramines in water treatment is affected by several factors, including the type of chloramine, concentration, contact time, and water quality conditions. Organic matter, turbidity, and other impurities in the water can also affect the disinfection effect of chloramines. If necessary, the water can be pre-treated to improve the disinfection effect.

By-Products And Hazards of Chloramine Disinfection

By-Products

Although monochloramine produces fewer traditional disinfection byproducts (DBPs) such as trihalomethanes (THMs) compared to free chlorine, it still generates some specific byproducts, including:

| Byproducts | Description |

| N-Nitrosodimethylamine (NDMA) | Highly carcinogenic by-products with health risks even at very low concentrations |

| Chlorinated Amines | Includes monochloramine, dichloramine, trichloramine, may cause odor and irritation |

| Bromination By-Product | If bromide ions are present in the source water, organic bromine by-products (e.g., brominated trichloromethane) may be generated |

| Ammonia Accumulation | Chloramines decompose to produce free ammonia, which promotes the growth of bacteria (especially nitrifying bacteria) in the water system. |

Table Of By-Products

Chloramine disinfection, while effective in reducing traditional by-products like trihalomethanes (THMs), introduces its own set of hazards. One major concern is the formation of N-nitrosodimethylamine (NDMA), a highly carcinogenic compound even at very low concentrations. Prolonged exposure to chloraminated water can also cause irritation to the eyes, skin, and respiratory system. Additionally, chloramine can contribute to nitrification, leading to elevated ammonia levels, oxygen depletion, and unpleasant taste and odor issues in the water supply. Over time, chloramine-treated water may accelerate the corrosion of metal pipes and fittings, particularly copper piping. Moreover, compared to free chlorine, chloramine disinfects more slowly, making it less effective in rapidly controlling sudden microbial contamination events.

Chloramines, Chlorine And Chlorine Dioxide Differences

| Characteristics | Chloramines | Chlorine | Chlorine dioxide |

| Chemical formula | May be Cl2(NH2) or Cl(NH2)2 | Cl2 | Cl2O2 |

| Compound type | Chloramine is a mixture of chlorine and ammonia | Chlorine | A mixture of chlorine monoxide |

| Oxidized state | May contain nitrogen | Nitrogen free | Contains oxygen |

| Main application | Disinfectant in water treatment | Disinfectant in water treatment | Disinfectant in water treatment |

| Sterilization mechanism | Releases chlorine ions to kill microorganisms | Releases chlorine ions to kill microorganisms | Releases chlorine ions to kill microorganisms |

| Form | Gas or solid | Gaseous form | Gas or liquid form |

| Safety | Relatively safe | Toxic, use with caution | Relatively safe |

| Storage and transportation | Relatively simple to store and transport | Compressed gas, special containers required | Compressed gas, special containers required |

Chloramines Application Process In Water Treatment

Chloramines preparation

Chloramines are produced by mixing chlorine with ammonia under controlled conditions, typically using specialized equipment. This preparation is usually carried out within a chlorine generation unit, supported by a chemical dosing system. The dosing system enables the continuous preparation and precise injection of chloramine, ensuring stable chloramine concentrations in the boiler water. Moreover, the system can be adjusted based on specific boiler water conditions, such as modifying the chlorine and ammonia dosing rates, adjusting the mixer speed, and optimizing operational parameters to achieve the best disinfection and corrosion control outcomes.

Chloramines Dosing

Prepared chloramines are added to the water treatment system. Chemical injection is available and chloramine can be delivered in gas or liquid form depending on the application requirements. Liquid chloramines can be accurately dosed by submerged metering pumps, while gaseous chloramines are usually added to the water by proportioning pump or injectors.

Liquid chloramines are usually added using one or more metering pumps, which precisely control the amount of gas injected into the water. The type of pump used can vary depending on the size of the treatment required and the specific characteristics of the water source. These pumps can be manual or automatic, and more sophisticated systems use sensors and control algorithms to adjust dosing in real time based on measurements of water quality parameters.

If large quantities of chlorine dioxide are required, HZ mechanical dosing pumps with high output flow rates may be needed. Mechanical dosing pumps usually have highly accurate flow control and can be adjusted over very small dosage ranges. Small quantities of chloramine can be metered into miniature diaphragm metering pump.

For precise control of chloramine dosing pumps, solenoid dosing pump of the H series can be used. They have adjustable flow control and are suitable for applications requiring frequent dosage adjustments, while electromagnetic metering pumps can also be used for the addition of gaseous chloramines.

Chloramines are corrosive chemicals that may cause corrosion of the pump material. Selecting pump materials with good corrosion resistance, such as HY-D hydraulic metering pumps, will increase the service life of the pump.

Mixing and Reacting

Chloramines are added to react with microorganisms and organic matter in the water. In rapid mixing for water treatment, to ensure that the chloramine reacts adequately with the microorganisms and organisms in the water, it is necessary to use an agitator or mixer to mix rapidly in a agitator tank. The agitator helps to disperse the chloramine evenly in the water, thus accelerating the release of chlorine ions and the disinfection process of the microorganisms.

Adjustment Of Chloramine Dosage

Based on the monitoring results, the dosage of chloramine can be adjusted according to the water quality condition and flow rate to maintain the disinfection effect and avoid exceeding the residue limit.

Chloramine vs. Other Sterilizations

Chloramines: Suitable where long distance water distribution and retention of disinfectant residue in water is required (e.g. urban water supply networks), but sterilization is slow and the risk of by-products (e.g. NDMA) needs to be controlled.

Ultraviolet light: Suitable for immediate sterilization, no by-products, but can not provide subsequent protection, often used in the outlet or end of the enhanced disinfection.

Ozone: Extremely strong sterilization effect, can also remove odor and color, but the process is complex, high cost, suitable for high standard water treatment system.

Safety Precautions for the Use of Chloramine

The use of chloramines is a complex process involving both chemical safety and water treatment safety. The following are safety considerations when using chloramines, both in terms of the safety of the treatment chemicals themselves and the safety of the water being treated.

- Personal Protective Equipment (PPE): Appropriate personal protective equipment (PPE), including goggles, chemical-resistant gloves, protective clothing, and respiratory protective equipment (RPE), must be worn when handling chloramines. This equipment reduces the risk of exposure to chloramines.

- Ventilation and work environment: Ensure that the work area has adequate ventilation to reduce chloramine vapor concentrations. Operators should avoid operating in confined environments.

- Storage: Store chloramines in specialized containers away from heat, ignition sources and other chemicals. Containers should be clearly labeled and warning signs should be placed in the storage area.

- Prohibition of mixing: Chloramines should not normally be mixed with other chemicals, especially strong acids, bases or organics. When using chloramines, mixing should be avoided to prevent harmful gases or chemical reactions.

- Emergency Response: Establish an emergency response plan, including procedures for disposal of spills or accidents. Operators should know how to respond to emergencies, including chloramine spills.

Summary

Chloramine is a chemical used in water treatment and disinfection. Its main function is to kill or inhibit the growth of microorganisms in water.

HAOSH handles all design aspects, requirements, parts, field, and customer support for static mixers, metering pumps, accessories, backpressure valves, and dosing systems. Contact HAOSH for an equipment quote or to inquire about a solution.