Tank Agitator Mixer

Tank agitator, usually a tank agitator mixer mounted on the top or side of a container.

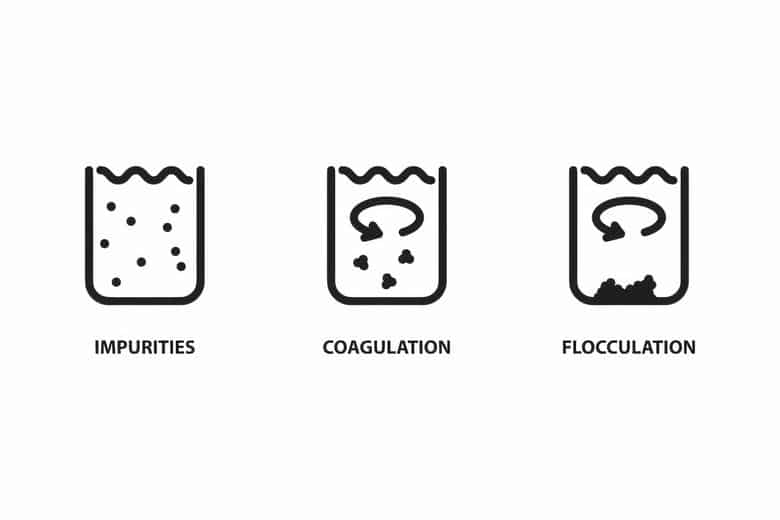

In the wastewater treatment industry, it is usually installed on the dosing tank for mixing water treatment chemicals. The resulting chemical solution is then fed through a dosing pump to a designated water treatment tank.

Widely used in the industry, as a variety of pharmaceutical, solution and other substances mixed economic, rapid solution.

A tank agitator, usually, is a tank agitator that is mounted on the top or side of a vessel.

In the wastewater treatment industry, it is usually installed on the dosing tank to stir and mix water treatment chemicals. And then these made chemical solutions are injected into the designated water treatment tanks through dosing pumps.

The industry has a wide range of applications as an economical and fast solution for mixing various types of chemicals, solutions and other substances.

The impellers of the mixer are usually in one set, and depending on your application needs, multiple sets of impellers, different impeller shapes, etc. can also be customized.

How the tank mixer works?

An electric motor transmits the energy required for mixing directly or through a gearbox to the mixing shaft. The shaft rotation drives the unique impeller of the mixer. Due to the efficient axial pumping action on the fluid in the tank, the impeller motion produces high flow rates and low shear. This results in efficient mixing of the entire contents of the tank.

Method of installation

The tank can be used with any medicine pump,calculation pump and is widely used in water treatment projects.

Applications

- Water and wastewater treatment

- Petrochemical

- Electroplating

- Textile printing and dyeing

- Pharmaceutical

- Food

- Pickling

- Liquid storage

- Blending containers

Structure material (optional): 304 stainless steel, 316 stainless steel, 316L stainless steel, lined with epoxy resin, painted PTFE