What is Chemical Feed System?

Chemical feed system is an essential component in many industrial and water treatment processes, providing precise control over the addition of chemicals to a system. Whether used to treat wastewater, control pH levels, or disinfect water, chemical feed systems play a crucial role in ensuring the efficient and safe operation of these processes. These systems are designed to accurately deliver chemicals in the right quantities at the right time, making them vital in various industries, including water treatment, chemical processing, and food production.

What is chemical feed system?

Chemical feed system automatically injects chemicals for water or wastewater treatment into the chemical feed tank. During dosing, chemical metering pumps are used to precisely control the rate at which chemicals are added to the water stream.

Application of chemical feeding system

- Municipal water supply: disinfection systems, sodium hypochlorite, pH adjustment, fluoride addition

- Municipal wastewater: flue gas scrubbers, odor control, pH adjustment, coagulation and flocculation

- Food and beverage: in-situ cleaning, off-line cleaning, sterilized water treatment

- Institutional: cooling tower waste treatment, boiler water treatment, closed-loop systems, scale inhibitor addition

- Other applications: swimming pools and water parks, mining and agriculture, utilities and dairy industries, pulp and paper, oil and gas operations, crude oil processing

What are some common injectable chemicals?

Chemical dosing systems are used in water treatment applications that require mixing, storage and precise dosing of chemicals. Adding the correct chemical at the optimum rate is important to achieve the best long-term application performance.

- Citric Acid: The most commonly used pH treatment method. Use citric acid in chemical doses.

- Chlorine: The most commonly used method of water disinfection. Ideal for drinking water disinfection. Chemical injection using calcium hypochlorite or sodium hypochlorite.

- Dechlorination: The most common method of dechlorination. Uses chemical doses of sodium bisulfite.

- Peroxyacetic Acid: PAA is an excellent disinfectant and sanitizer for industrial water and wastewater treatment. pAA can be injected using diaphragm pumps or peristaltic chemical pumps. Peroxyacetic acid is an effective and safe alternative to chlorine. It is an oxidizing bactericide that degrades relatively quickly to non-toxic by-products.

Standard structure of chemical feeding system

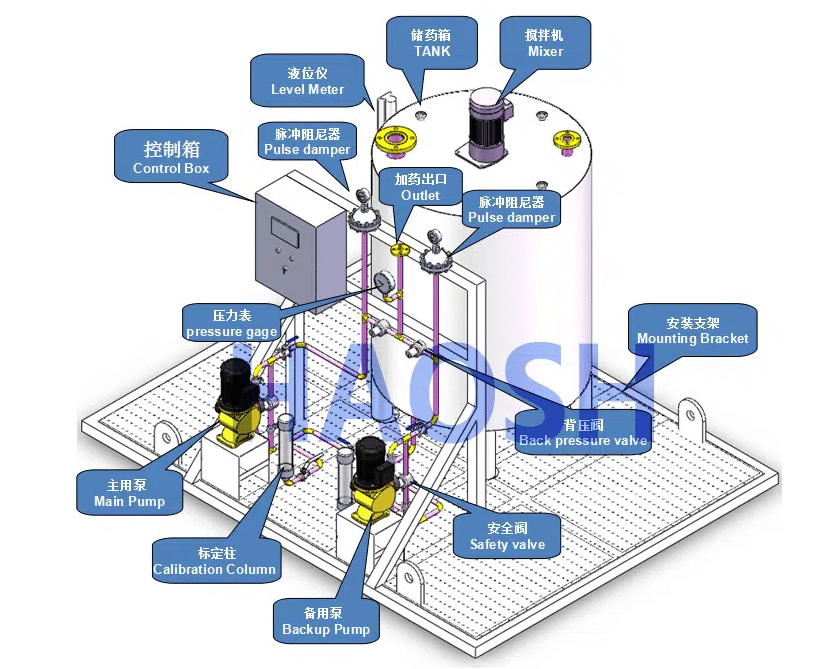

Chemical dosing systems are usually customized. A conventional dosing system design is shown below:

Chemical feed systems are usually supplied as complete, fully integrated units already mounted on a chute, or components can be purchased separately. The main components of such systems are

- Chemical storage tanks

- Liquid mixers

- Positive displacement pumps

- Piping

- Process control panel

- Skid mounted structures

- Flow indicators (usually float flow meters or electromagnetic flow meters)

- Safety and backpressure valves

- Y-strainers

- Static mixer

Types of pumps for chemical feed systems

Solenoid driven metering pumps – The simplest design and the least expensive metering pump available. The solenoid controls a spring-loaded reset piston that pushes out a specific amount of fluid on each stroke. The flow rate is regulated by increasing the frequency of the strokes. This type of pump is suitable for low flow applications.

Motor-driven metering pumps – Designed to handle high flow processes, such as water treatment facilities. In these applications, the chemistry of the water must be closely analyzed and controlled. The design includes a flexible diaphragm controlled by a motor and an adjustable stroke lever. The flow rate is controlled by varying the diaphragm stroke frequency (motor speed) and the amount of chemical delivered per stroke (diaphragm stroke length). In complex water treatment systems with multiple pumps, motor speed can be controlled by water flow rate and a chemical analyzer can be used to control chemical delivery.

Summary

In conclusion, chemical feed systems are indispensable tools for ensuring the effectiveness of water treatment and industrial processes. With the right system in place, businesses can achieve precise chemical dosing, improve operational efficiency, and maintain the highest standards of safety and environmental protection. Investing in a reliable and efficient chemical feed system not only enhances process performance but also contributes to the overall sustainability of the operation.

KUOSI offers a comprehensive range of services designed to meet the unique needs of each customer. We believe in building strong, lasting relationships through clear communication, expert technical support, and exceptional service. Let’s work together to achieve your business goals and improve your environmental impact! Please contact us if you need help.