Pump Of Pressure Relief Valve

Pressure relief valves are the primary protection for personnel and equipment involved in static and dynamic pressure systems. They are used to control or limit pressure in a system or vessel due to process disturbances, instrument or equipment failure, or fire. Pressure relief valves are essential for keeping hydraulic and pneumatic systems below set pressure.

What is a pressure relief valve?

A pressure relief valve is a valve used to control the pressure of a system or piece of equipment to ensure that excessive pressure does not occur below a set pressure threshold. Its primary function is to release excess fluid to prevent overpressurization of the system. Pressure relief valves are typically designed to open when a predetermined pressure is reached, releasing excess fluid or gas from the system, thereby protecting the system from damage.

Principle Of Operation Of Pressure Relief Valves

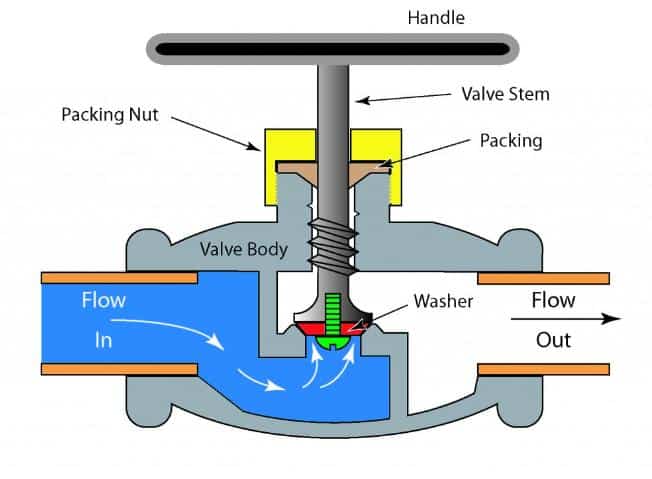

The pressure relief valve consists of three functional elements:

Valve element (poppet)

Pressure relief valves utilize a spring loaded “poppet” valve as the valve element. Poppet valves include an elastomeric seal, or in some high-pressure designs a thermoplastic seal, which is configured to form a seal on the valve seat. In operation, a spring and upstream pressure exert opposing forces on the valve. When the upstream pressure exerts a force greater than the spring force, the poppet valve moves away from the seat, thereby allowing fluid to pass through the outlet port. When the upstream pressure drops below the set point, the valve closes.

Sensing element (piston or diaphragm)

Piston designs are often chosen when higher relief pressures are required, when ruggedness is a concern, or when precise relief pressures do not need to be maintained. Piston designs are relatively slow moving due to the high friction of the piston seal. At low pressures or where high accuracy is required, the diaphragm type is preferred. Diaphragm safety valves utilize a thin, disk-shaped element that senses pressure changes and is usually made of an elastomeric material, but can also be made of thin corrugated metal. Compared to piston designs, diaphragms essentially eliminate friction. In addition, diaphragm designs typically provide a larger sensing area for the same size relief valve.

Reference force element (spring)

Typically, the reference force element utilizes a mechanical spring, and this spring applies force to the sensing element and is responsible for closing the valve. Many pressure relief valve designs include adjustment devices that allow the user to change the relief set point by adjusting the force of the reference spring.

A set pressure threshold is maintained in the system. When the system pressure exceeds this threshold, the pressure relief valve opens, allowing fluid to flow out or gas to be released, thereby reducing the system pressure. When the pressure drops to within the set range, the valve closes, preventing further venting.

Pressure relief valve application industry

Pressure relief valves are widely used in a variety of industrial, hydraulic and pneumatic systems to ensure safe operation of the system.

Types of pressure relief valves

- Direct Acting Pressure Relief Valve: A pressure relief valve that acts directly on pressure by directly sensing pressure changes and generating a corresponding response.

- Balanced Pilot Operated Pressure Relief Valve: Controls the opening and closing of the main valve by means of an auxiliary control loop, known as the pilot valve, resulting in a smoother and more precise valve action.

- Remote Operated Pressure Relief Valve: Operation of the pressure relief valve can be realized through a remote control device, such as an electrical or pneumatic device, for scenarios that require remote control.

- Electric Pressure Relief Valve: An electric device, usually an electric actuator, is used to realize the operation of the pressure relief valve, which is controlled by an electric signal, and is suitable for automated systems.

These types of pressure relief valves have specific advantages and applicability in different application scenarios, and the choice depends on the specific requirements and performance needs of the system.

Pressure Relief Valve Applications

Avoid Cavitation

The risk of cavitation increases when the liquid pressure drops rapidly below the vapor pressure. Particularly in centrifugal pumps pumping closed systems, the overpressure in the discharge pump casing can lead to low pressure areas that may cause cavitation. By opening proportionally with increasing pressure, the safety valve bypasses the casing. This slowly releases the excess pressure. To alleviate this problem, install safety valves that open proportionally to pressure to vent excess pressure inside the pump casing.

Cooling/Heating Circuit

Sudden changes in flow rates can occur. Reactions connected to a boiler or reactor may result in pressure rises or falls that are disproportionate to the input generated by equipment such as pumps and heat exchangers. To avoid unexpected pressure changes in heating circuits, pressure relief valves are a useful option.

Systems With Sensitive Equipment

For systems with sensitive equipment, excessive pressure can cause damage to the equipment. By using pressure relief valves, premature equipment failure can be prevented and included in preventive maintenance programs.

The Difference Between A Pressure Relief Valve And A Safety Valve

| Features | Pressure Relief Valves | Safety Valve |

| Main functions | Releases excess pressure in the system. | Opens when the pressure in the system exceeds the set point, releasing excess pressure. |

| Trigger mechanism | Based on preset pressure thresholds. | Based on the pressure reaching or exceeding the set point. |

| Operation methods | Active pressure release. | Passively responds to overpressure. |

| Positioning | Usually on the low pressure side of the system. | Typically located on the high-pressure side of the system. |

| Pressure control range | Controlled pressure over a range. | Set for a specific pressure value. |

| Handling after pressure release | Continuous release of excess pressure. | Closes when pressure returns below set point. |

| Field of application | Versatile for a wide range of fluid systems. | Mainly used in steam and gas systems. |

Safety valves and pressure relief valves have the same general purpose. Both are pressure relief valves designed to relieve pressure in any situation where the system is overpressurized. That said, pressure relief valves and safety valves do have slightly different functions.

Where do pressure relief valves typically function?

Dosing systems refers to the process of adding chemicals or other substances to another fluid. In dosing systems, metering pumps are often used to deliver chemicals or other substances. During the mixing process of the agitator, the pressure is generally relatively stable and excessive pressure will not occur. During the pumping process, higher pressure will be generated due to the faster fluid flow rate. If the pressure is too high, the pump may be damaged or even explode. Therefore, a pressure relief valve needs to be installed to prevent excessive pressure during the pumping process.

Pumps Suitable For Pressure Relief Valves

Pressure relief valves are often used with pumps in liquid or gas transfer systems to ensure that the pressure in the system remains within safe limits. Below are some common types of pumps used with pressure relief valves:

Centrifugal pumps: Centrifugal pumps are common pumps for transferring liquids and are widely used in industry and construction. Pressure relief valves can be used with centrifugal pumps to prevent overpressurization in piping or systems.

Reciprocating pumps: Reciprocating pumps propel liquids through the movement of a plunger and are commonly used in applications requiring high pressures. In this case, a pressure relief valve can be used to relieve excess pressure and prevent overloading the system.

Diaphragm metering pumps: Diaphragm metering pumps produce fluid flow through the movement of a diaphragm and are used in applications handling a wide range of liquids. Pressure relief valves can be used to ensure that proper system pressure is maintained during pump operation.

Screw pumps: Screw pumps move fluid through the rotation of a screw and are commonly used for high viscosity liquids. Pressure relief valves can be used to ensure that the system is within safe operating limits at all times.

Sewage pumps: Pumps used to discharge sewage. In these applications, pressure relief valves can be used to control and maintain pressure in the discharge system.

How to choose the right pressure relief valve?

System requirements: Determine the design pressure range, operating temperature, and flow requirements of the system. These parameters will help determine the pressure relief valve rating.

Valve type selection: Depending on the system requirements, select the appropriate type of pressure relief valve, such as spring-loaded, modulating, or hydraulic. Different types of pressure relief valves are suitable for different application scenarios.

Pressure Rating: Select the pressure rating of the pressure relief valve based on the system pressure range. Ensure that the pressure rating range of the selected relief valve covers the maximum operating pressure of the system.

Flow requirements: Consider the maximum flow rate of the system to ensure that the flow characteristics of the pressure relief valve meet the system requirements.

Material selection: Select the appropriate material based on the nature of the fluid and the operating environment. Typically, the body and seal material of a pressure relief valve should be compatible with the fluid and able to withstand the operating conditions of the system.

Installation location: Where a relief valve is installed is critical to its performance. Be sure to install a pressure relief valve in the proper location to ensure that it will respond quickly and relieve excess pressure in the system.

Summary

A pressure relief valve is a safety device that protects a pressurized vessel or system during an overpressure event. Pressure relief valves must be able to operate at all times, especially during power failures when system controls are not functioning. Therefore, the only source of power for a pressure relief valve is the process fluid.

HAOSH specializes in the development of dosing pumps and systems, offering hydraulic dosing pumps, pump accessorie, submersible mixer and chemical dosing systems. Please contact us if you have any questions.