Peristaltic Pump VS Diaphragm Pump

Peristaltic pumps and diaphragm pumps are both common choices in the field of liquid transfer and handling. They each utilize unique operating principles for different application scenarios. This article provides an in-depth comparison of peristaltic and diaphragm pumps to help you understand how to choose the right pump for your needs.

Understanding Peristaltic Pumps

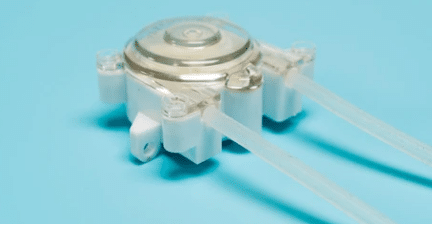

What is a peristaltic pump?

A peristaltic pump is a type of pump used for liquid transfer that works similar to the peristaltic movement of the human esophagus. Peristaltic pumps push liquids from one place to another in a unique way without any moving parts coming into direct contact with the liquid. The main components of a peristaltic pump include a flexible tube or peristaltic, one or more squeezing devices (such as rollers or rubber blades), and an electric motor or manually operated device.

how it works?

Peristaltic: The peristaltic is the core component of a peristaltic pump and is usually made of flexible tubing or piping system that can withstand a wide range of liquids, including corrosive liquids. The peristaltic device seals the liquid inside and exposes the outside to the action of the extruder.

Extrusion Device: The extrusion device in a peristaltic pump, usually a roller or rubber piece, mechanically or electrically squeezes the outer surface of the peristaltic back and forth. The movement of this extruder creates a peristaltic effect, causing the outer surface of the peristaltic device to be periodically compressed and relaxed.

Liquid movement: As the extrusion device squeezes the peristaltic device, this peristaltic effect pushes the liquid along the length of the peristaltic device. The fluid is encapsulated within the peristaltic, drawn in through one port and pushed out through another. This movement can be sustained for continuous fluid delivery.

Directional flow: The direction of motion of the extruder determines the direction of liquid flow. Typically, peristaltic pumps allow for unidirectional flow, where the liquid enters through one port, passes through the peristaltic, and exits through the other port.

Precise flow control: Peristaltic pumps have very precise flow control because it is achieved by squeezing the frequency and squeeze pressure of the peristaltic device. By adjusting the speed and amplitude of the squeeze, the volume and speed of the liquid delivered can be easily controlled.

The unique operating principle of peristaltic pumps makes them useful in many applications, especially where precise flow control is required, to avoid cross-contamination or to handle aggressive liquids. It is commonly used in laboratories, medical devices, food processing, water treatment, pharmaceuticals and chemicals. Advantages of peristaltic pumps include precise flow control, simple maintenance, low risk of contamination and wide applicability.

Understanding Diaphragm Pump

What is diapgragm pump?

A diaphragm pump, also known as chemical feed pump or proportioning pump, is a common type of pump used for liquid and gas transfer. Its main feature is the use of a flexible diaphragm to separate the pump’s internal chamber from the pump’s external environment in order to propel liquids or gases. Diaphragm pumps are typically used in a wide range of applications where high pressure, no leakage, precise flow control or handling of corrosive liquids is required.

Diaphragm metering pumps are positive displacement pumps designed to be used as proportional metering pumps. These pumps use a flexible diaphragm to move the chemical solution through the pump. A piston or plunger alternately bends the diaphragm to create the pumping action.HAOSH H Electromagnetic Metering Pumps are well suited for applications where the chemical solution is corrosive or abrasive.

how it works?

- At the start of the pump, the diaphragm of a diaphragm pump expands on the suction side of the chamber and contracts on the discharge side. This causes the suction valve to open and draw in the liquid or gas.

- As the drive mechanism moves, the diaphragm gradually deforms, compressing the liquid or gas in the suction chamber and pushing it into the discharge chamber.

- As the diaphragm continues to compress, the pressure in the discharge chamber increases and the discharge valve opens and discharges the liquid or gas.

- The movement of the diaphragm is cyclical, expanding and contracting to continuously push the fluid. This movement creates a continuous flow process.

Advantages and disadvantages of peristaltic pumps and diaphragm pumps

| Feature | Peristaltic Pump | Diaphragm Pump |

| Operating Principle | Characterized by a low shear effect because the liquid is squeezed and released without involving high speed rotation or agitation. | Uses a diaphragm to separate pump chambers and push fluids through diaphragm expansion and contraction. |

| Leakage Risk | Low risk of leakage since the liquid doesn’t come into contact with pump’s mechanical components. | No leakage risk due to complete isolation of liquid from the external environment by the diaphragm. |

| Precise Flow Control | Offers highly precise flow control, suitable for applications requiring accurate dosing. | Flow control is typically precise, though slightly less accurate compared to peristaltic pumps. |

| Easy Maintenance | Relatively easy to maintain, mainly involving tube or peristaltic head replacement. | Also relatively easy to maintain, usually requiring diaphragm replacement. |

| Durability | Peristaltic tubes are wear-resistant but need periodic replacement. | Diaphragms generally have a longer lifespan but require regular inspection and replacement. |

| High-Pressure Use | Suitable for high-pressure applications, but may require multiple pump heads. | Suitable for high-pressure applications, capable of generating high pressures without damaging the pump. |

Limitations of peristaltic and diaphragm pumps

Both peristaltic pumps and diaphragm pumps have limitations. Peristaltic pumps may require more frequent tube replacements, limiting their continuous use, while diaphragm pumps, although durable, may be costlier and less precise in flow control compared to peristaltic pumps. The choice depends on specific application needs, balancing factors like maintenance frequency, cost, and precision.

Is peristaltic or diaphragm pump a better choice in chemical dosing systems?

In chemical dosing systems, diaphragm pumps are often chosen to be used. This is because diaphragm pumps have the following advantages:

- corrosion resistance: Chemical dosing systems usually need to handle corrosive chemicals, and the diaphragm pump’s diaphragm can effectively isolate the liquid from the mechanical parts of the pump, thus reducing the risk of corrosion of the pump.

- Accurate flow control: Chemical dosing usually requires accurate dosage control, and diaphragm pumps are usually able to provide more accurate flow control to ensure accurate dosing of chemicals.

- No Leakage: Diaphragm pumps are designed to effectively prevent leakage, which is critical when handling chemicals, reducing environmental contamination and safety risks.

- Durability: Diaphragm pumps typically have a long service life, allowing for continuous operation in chemical dosing systems, reducing downtime and maintenance costs.

In summary, although peristaltic pumps can be used in chemical dosing systems in some cases, diaphragm pumps are generally better suited for this application because they offer better handling of corrosive liquids, more precise flow control and greater reliability.

How to choose the right pump for you?

Selecting the right pump requires consideration of several factors, including application requirements, fluid properties and budget.

Application Requirements

- Flow Requirements: Determine how much flow you need to meet the needs of the application.

- Pressure Requirements: Consider how much pressure the liquid needs to be delivered.

- Flow Control: Peristaltic pumps are often better suited if precise flow control or dosage delivery is required.

- Pump Continuity: Determine if the pump is required to run continuously or can be operated intermittently.

Liquid Properties

- Liquid viscosity: peristaltic pumps are suitable for low to medium viscosity liquids, while diaphragm pumps are more suitable for high viscosity liquids.

- Liquid corrosivity: If handling corrosive liquids, choose a pump with corrosion-resistant materials.

- Solid particles: If there are solid particles in the liquid, consider whether a specially designed pump is required to handle them.

Maintenance Requirements

- Maintenance Frequency: Understand the maintenance requirements of the pump, including the frequency of parts replacement.

- Maintenance complexity: Consider how easy maintenance is to perform and whether specialized knowledge is required.

Summary

Peristaltic pumps and diaphragm pumps are two common choices in the field of liquid transfer and handling. They utilize their own unique operating principles and are suitable for different application scenarios.

HAOSH offers a wide range of water treatment dosing products and solutions, mainly providing dosing metering pumps, agitators, pump accessories and dosing systems, welcome to contact us.