What Is the Role of Chlorine Dioxide in Water Treatment?

What is chlorine dioxide?

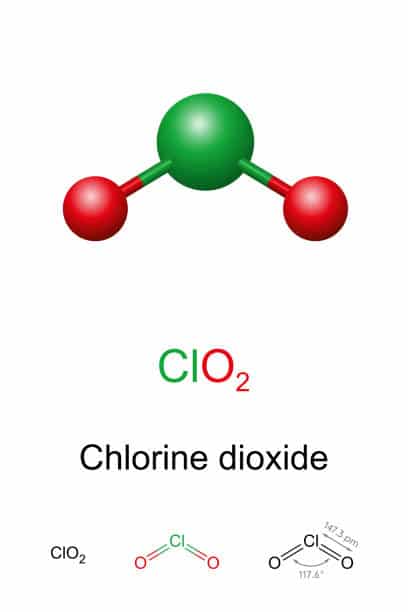

Chlorine dioxide (ClO2) is a chemical substance that exists as a yellow-green gas at room temperature and pressure, has an irritating odor, and can form a light yellow solution in water. It is a strong oxidizing agent, and its main use is as a disinfectant in the water treatment process.

Properties of chlorine dioxide

- Chemical properties: Chlorine dioxide is a strong oxidizing agent, which can react rapidly with many substances, including some difficult to oxidize substances. But unlike chlorine, chlorine dioxide will not form chlorides in the reaction.

- Stability: Chlorine dioxide is not stable at room temperature and decomposes easily, so it needs to be generated on site at the place of use.

How effective is chlorine dioxide as a disinfectant?

Chlorine dioxide is a highly effective disinfectant that kills bacteria, viruses, fungi, algae and other microorganisms. It disrupts microbial biofilms, which are resistant to many other disinfectants. In addition, chlorine dioxide does not react with organic substances in the water to form potentially harmful disinfection by-products such as trihalomethanes and halogenated acids. Chlorine dioxide is also effective in removing color and odor from water during water treatment to improve water quality.

What is the role of chlorine dioxide in water treatment?

Use of chlorine dioxide in water treatment

Chlorine dioxide (ClO2) is widely used in the water treatment process. As a powerful disinfectant, it can not only efficiently kill various microorganisms in the water, but also hardly reacts with organic matter in the water to generate potentially harmful disinfection by-products during the disinfection process, which is one of its major advantages. This is the main reason why it is widely used in drinking water and wastewater treatment. In addition, chlorine dioxide can also be used in industrial water treatment, such as cooling water and boiler water treatment, where it can effectively control the growth of algae and prevent clogging of pipes.

Disinfection of chlorine dioxide in water treatment

In the disinfection process, chlorine dioxide prevents microorganisms from surviving mainly by disrupting their vital activities, such as the metabolic activities of bacteria, viruses and algae. Chlorine dioxide is highly effective in killing all types of microorganisms, including those that are highly resistant. In many cases, chlorine dioxide is the only disinfectant that is effective in killing specific types of microorganisms. In addition, since chlorine dioxide is not susceptible to side reactions with organic substances in the water, its disinfecting ability is not significantly affected by organic substances in the water, which is a major advantage of its use as a disinfectant.

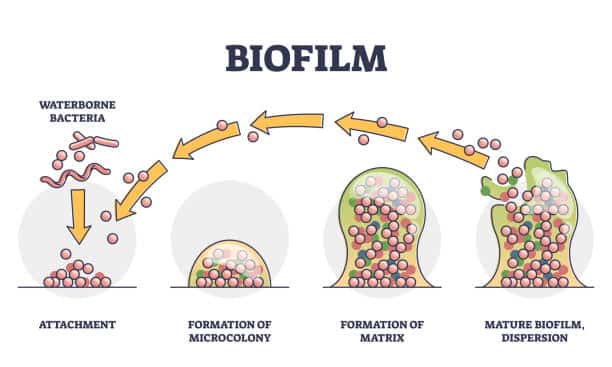

The role of chlorine dioxide in preventing biofilm formation

Biofilm is an organic substance formed by microorganisms such as bacteria and fungi, which form a protective layer on various surfaces and impede the action of disinfectants. Chlorine dioxide is also remarkably effective in this regard, penetrating and destroying the biofilm so that the disinfectant can effectively kill the microorganisms within the biofilm. This effect is important in preventing and controlling biofilm formation in pipelines, tanks and other facilities.

What is the difference between chlorine dioxide and other disinfectants?

When we consider chlorine dioxide, chlorine and bromine as water treatment disinfectants, each has its specific advantages and disadvantages. The following is a basic comparison of them:

| Disinfectant | Chlorine Dioxide | Chlorine | Bromine |

| Mechanism of Action | Directly penetrates cell wall and disrupts metabolism of microorganisms | Forms hypochlorous acid that oxidizes proteins in microorganisms | Forms hypobromous acid which can penetrate cell wall and oxidize cell constituents |

| Effectiveness | High kill efficiency against bacteria, viruses, and protozoa | Effective against most bacteria and viruses but less effective against protozoa | Effective against most bacteria and viruses but less effective against protozoa |

| Factors Affecting Efficiency | Unaffected by pH and minimally impacted by organic matter | Efficiency decreases with increasing pH and organic matter | Efficiency decreases with increasing pH and organic matter |

| Production of Disinfection By-Products | Produces minimal by-products, mainly chlorite | Can produce trihalomethanes and other harmful by-products | Can produce trihalomethanes and other harmful by-products |

| Scope of Application | Broad-spectrum, suitable for various water conditions | Broad, but less effective in high pH and organic matter conditions | Broad, but less effective in high pH and organic matter conditions |

Here are some emphasized points about chlorine dioxide:

- Highly efficient inactivation: Chlorine dioxide has a high disinfection effect, it can effectively kill a variety of microorganisms, including drug-resistant bacteria. This makes chlorine dioxide advantageous in many complex water treatment applications.

- Resistant to the effects of organic matter: In many disinfection processes, organic matter in the water will affect the effectiveness of the disinfectant. However, the disinfecting ability of chlorine dioxide is not significantly affected by these substances, which makes chlorine dioxide more advantageous in water treatment applications with high organic content.

- Low by-product generation: Many disinfectants react with organic substances in the water during use, generating potentially harmful by-products. In contrast, chlorine dioxide almost does not generate these by-products, this feature makes it more advantageous in drinking water treatment and other water quality requirements of the occasion.

- Prevent biofilm formation: Chlorine dioxide has the ability to destroy biofilm, which makes it in the pipeline and the maintenance of facilities occupies an important position, can prevent biofilm damage to the facilities and microbial regrowth.

The process of using chlorine dioxide in water treatment

The application of chlorine dioxide in water treatment systems involves a series of steps and considerations:

Generation of chlorine dioxide

Chlorine dioxide is normally generated on-site at the point of use and can be produced by a chemical reaction (e.g., acid-chlorate reaction or chlorine-chlorate reaction). Chlorine dioxide generators are the main equipment for such generation.

Dosage determination

The dosage of chlorine dioxide depends on a number of factors, including water quality conditions (e.g., microbial load, organic content, etc.), water treatment objectives (e.g., disinfection or biofilm control), and system characteristics (e.g., water flow rate, water temperature, etc.). The dosage of chlorine dioxide is usually determined through laboratory or field trials to ensure that it achieves the treatment objectives without over-disinfection causing unnecessary costs or side effects.

Chlorine dioxide addition

The addition of chlorine dioxide to water systems can be a complex process. This is due to the strongly oxidizing nature of the gas, which means it can react with many different substances. Therefore, a well-designed and precisely calibrated delivery system is necessary to ensure the correct dosage.

Chlorine dioxide is usually added using one or more metering pumps that precisely control the amount of gas being injected into the water. The type of pump used can vary depending on the size of treatment required and the specific characteristics of the water source. These pumps can be manual or automated, and more sophisticated systems use sensors and control algorithms to adjust the dosage in real time, based on measurements of water quality parameters.

If large quantities of chlorine dioxide are required, the H Solenoid Dosing Pump with a high output flow rate may be required. if only small quantities of chlorine dioxide are required, a miniature diaphragm metering pump may be more appropriate.

If precise control of the amount of chlorine dioxide added is required, the HJ-Z Mechanical Dosing Pump may be a better choice.

Chlorine dioxide is a strong oxidizer and may cause corrosion of the pump material. Selecting a pump material with good corrosion resistance, such as HY-D Hydraulic Dosing Pump, will increase the life of the pump.

Measurement and monitoring of chlorine dioxide

Measurement and monitoring are critical aspects of chlorine dioxide water treatment to ensure that chlorine dioxide concentrations are within the effective disinfection range and that dosage is adjusted in a timely manner. Measurement of chlorine dioxide is typically performed by colorimetric or electrochemical methods such as DPD or chloride ion selective electrode methods. In addition, regular microbiological testing is required to verify the disinfection effectiveness of chlorine dioxide.

What do I need to know about using chlorine dioxide?

The use of chlorine dioxide for water treatment requires consideration of two aspects of safety: the safety of the treatment chemical itself and the safety of the treated water.

Handling the safety of the chemical itself

Chlorine dioxide is a strong oxidizing agent and the possible effects on humans, materials and the environment should be of concern. During operation, direct contact with or inhalation of chlorine dioxide needs to be avoided as it may cause respiratory irritation, skin and eye burns, etc. Therefore, the use and storage of chlorine dioxide should follow the relevant safety regulations, including the use of appropriate protective equipment, the establishment of good ventilation, and regular safety training.

Safety of treated water

The safety of water treated with chlorine dioxide is intended for human consumption and use. Chlorine dioxide, as an effective disinfectant, can eliminate a wide range of harmful microorganisms, including bacteria, viruses and protozoa, thereby improving water hygiene. However, on the one hand, chlorine dioxide treatment needs to be controlled at the right concentration and duration to avoid the production of excessive disinfection by-products, which (e.g., chlorophenols and halogenates) may have an impact on human health. On the other hand, although chlorine dioxide is good at eliminating most harmful microorganisms, it may not be able to completely eliminate specific types of microorganisms (e.g., some hard-shelled viruses and encapsulated protozoa), and therefore needs to be combined with other water treatment steps (e.g., sedimentation, filtration, and ultraviolet (UV) disinfection) in order to achieve total water quality assurance.

Summary

Effective water treatment is essential to safeguard our lives and health. Chlorine dioxide plays a key role in this process by guaranteeing our access to a clean and safe water supply through efficient disinfection and is a vital tool in maintaining human health and environmental quality.

HAOSH, a global leader in fluid control equipment, specializes in dosing metering pumps and systems, offering dosing metering pumps, accessories, mixing agitators and dosing systems. We understand the importance of water and wastewater treatment to every community, which is why our dosing pumps are designed to help water treatment processes run efficiently. Feel free to contact us at any time.