Static Mixer For Pumps

The static mixer (is an in-line mixer that can be used to mix high and low viscosity liquids, slurries, and gases, as well as to perform reactions, heating/cooling, and multi-phase contacting. It can mix materials with the same or very different viscosities and volume flow rates.

Definition Of Static Mixer

What is a static mixer?

A static mixer is a device used to continuously mix fluid materials without the need for moving components. By means of chemical injection, typically the fluid being mixed is a liquid and is used to mix two or more different fluids or materials together without the need for any mechanical components or external energy sources. It can also be used for mixing gas streams, dispersing gases into liquids or mixing immiscible liquids Compared with traditional mechanical mixing methods, static mixers use a simpler and more efficient working principle.

Industrial Applications Of Static Mixers

- Chemical Processing

- Food processing

- Pharmaceuticals

- Water treatment

Advantages And Disadvantages Of Static Mixers

Pros

- No maintenance required.

- Suitable for all types of fluids.

- Suitable for a wide range of flow and pressure conditions.

Disadvantages

- May not mix as well as other mixers.

Working Principle Of Static Mixer

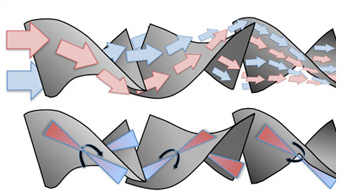

Static mixers utilize fluid flow to create turbulence for mixing without relying on mechanical stirring or agitators. Turbulence is a flow pattern in which small groups in a fluid flow in an irregular manner. Turbulence results in a full mixing of molecules between the fluids. There are many different designs of static mixers, often with specially designed internal structures that allow efficient mixing of fluids by adjusting the geometry of the tubes, the way they cross, and the speed at which the fluid flows.

- Segregation and recombination: Fluids are divided into small groups and then recombined. This causes the molecules between the fluids to collide with each other, resulting in mixing.

- Shear and Rotation: Fluids are subjected to shear and rotational forces during flow. These forces cause the molecules in the fluid to disperse into each other, resulting in mixing.

Types of static mixers

- Plate mixer: The use of parallel arrangement of thin plates or grids, the fluid through these plates or grids cross-laminar flow, prompting mixing.

- Static helical mixer : Through the static, non-rotating spiral structure, in the pipeline to guide the fluid to produce spiral flow, to achieve mixing.

- Crossflow mixer: Through the design of transverse cross channel, so that different fluids in the intersection of the mixing, to improve the mixing effect.

- Laminar flow mixer: Through the design of laminar flow structure in the pipeline, the fluid is mixed between layers to realize uniform mixing effect.

- Static mixing nozzle: A special shaped mixing nozzle is added to the pipeline to realize mixing by changing the direction and speed of the fluid.

- Other types: In addition to the above common types, there are other types of static mixers, such as honeycomb mixer, bellows mixer, spiral plate mixer and so on.

Differences Between Static Mixers And Other Mixers

| Characteristics | Static mixers | Other mixers |

| Moving parts | None | Have |

| Energy consumption | Low | High |

| Maintenance | Low | High |

| Applications | Suitable for all types of fluids | Suitable for specific types of fluids |

Static Mixers And Pumps

The selection of static mixers and metering pumps should be based on the type of media to be mixed, flow rate, pressure, viscosity and other factors. Static mixers have the advantage of requiring no maintenance and being suitable for all types of fluids and all flow and pressure conditions.

- Flow Requirements: The metering pump should be able to provide sufficient flow to meet the flow requirements of the static mixer.

- Pressure Requirements: If the static mixer is to be operated under high pressure conditions, the hydraulic dosing pump shall be capable of meeting the pressure requirements of the static mixer.

- Media type: The metering pump should be able to be adapted to the type of media to be mixed. For example, for corrosive media, corrosion-resistant metering pumps should be selected. Solenoid dosing pump are capable of metering virtually any liquid chemical.

- Viscosity requirements: metering pumps should be able to apply to the viscosity of the mixed media. For example, for high viscosity media, should choose a high viscosity performance metering pump.

Application Of Static Mixers In Dosing Systems

- Homogeneous mixing: Static mixers can effectively mix the water treatment flocculant with the fluid being treated, ensuring that each part contains the same proportion of the agent. This helps to improve the consistency and effectiveness of the treatment.

- Low shear: Static mixers typically have low shear, which is important for some shear-sensitive agents. Low shear helps to maintain the stability of the agent and prevents it from breaking down or becoming ineffective.

- Energy savings: Static mixers typically provide efficient mixing with lower energy consumption than some dynamic mixers.

- Small size: Static mixers are usually compact in design and take up relatively little space.

- Fast response: Static mixers are characterized by a fast response time and are able to adapt quickly to changes in flow rate.

- High reliability: Static mixers have no moving parts and therefore typically have a longer service life and require less maintenance, increasing the reliability of the dosing system.

Overall, static mixers provide efficient, economical and reliable mixing in chemical feed systems and are ideal for many dosing applications.

Summary

A static mixer is a device that utilizes the flow of the fluid itself to create turbulence for mixing. Static mixers have no moving parts and therefore require no maintenance.

HAOSH is a leader in water treatment dosing and metering, offering a comprehensive range of water treatment solutions including pump accessories, pulsation dampeners and dosing systems. With years of industry experience and expertise, we are committed to providing high quality, reliable water treatment products and services to our customers worldwide. Feel free to contact us for more information.