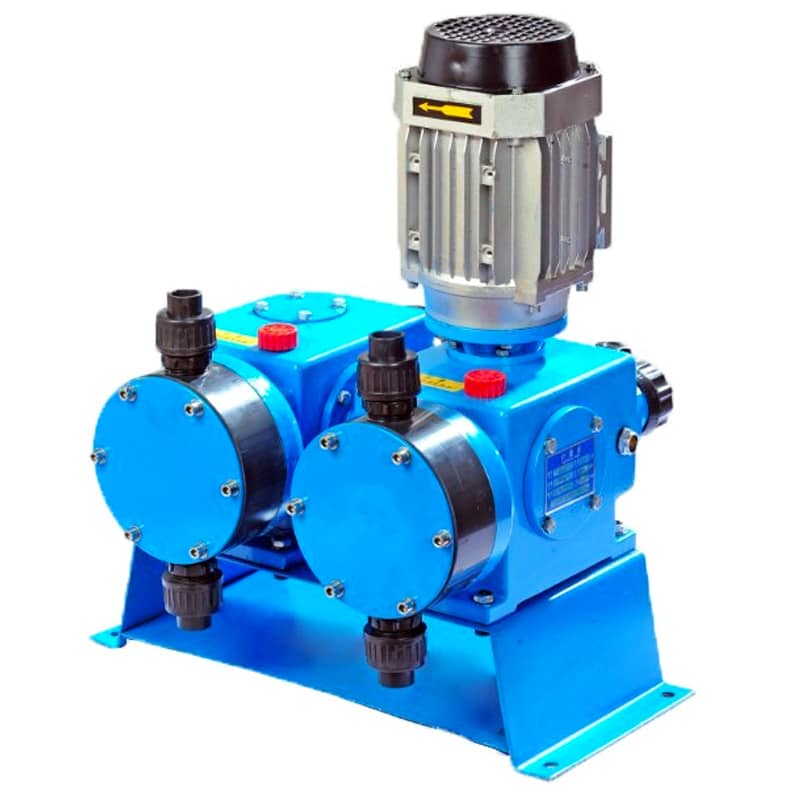

Inhibitor Dosing Pump

An inhibitor dosing pump is a pump used to drop an inhibitor into a system or process. An inhibitor is a substance added to a system to slow or stop certain chemical reactions, such as corrosion or fouling. Inhibitor dosing pumps are responsible for accurately and consistently putting the inhibitor into the system at the desired dose.

Working Principle

Supply of Inhibitors

First, the inhibitor is stored in a container, usually a component called a reservoir. This container can be a simple vessel or a closed system with a special design to ensure that the inhibitor is protected from the outside environment.

workflow

Inhibitor dosing pumps are operated by some mechanical or electric device to draw inhibitor from a reservoir and push it into the system where it needs to be dosed. The pump is usually equipped with a dosing control system to ensure that the amount of inhibitor being dosed is accurate and consistent. By adjusting the operating frequency or current of the electromagnetic actuator, the flow of inhibitor can be precisely controlled, resulting in accurate inhibitor dosing control. Once the inhibitor enters the system, it is evenly distributed to ensure effective protection against corrosion or scaling within the system. Inhibitor chemicals such as scale inhibitors, preservatives, biological inhibitors, etc.

advantages

Precise dosing: The inhibitor dosing pump can precisely control the amount of inhibitor dosed, ensuring that the required dose is dosed exactly when it is needed.

Automated control: Inhibitor dosing pumps equipped with a control system can be automated and dosed according to the needs of the system, reducing manual intervention and improving operational convenience and stability.

Wide applicability: Inhibitor dosing pumps are suitable for a variety of different types of liquid systems, including water treatment, chemical production,chemical treatment of wastewater, water supply systems, etc., which can meet the needs of different industries.

Disadvantages

Complex maintenance: Inhibitor dosing pumps involve mechanical and electronic components that require regular maintenance and servicing.

Power dependent: Inhibitor dosing pumps are often dependent on the power supply, and any power interruption or failure may affect the normal operation of the inhibitor dosing.

An inhibitor dosing pump is a device designed to control and dose inhibitors, commonly used in water treatment and cooling tower water treatment. Every community relies on water and wastewater treatment services, and the proper use of metering pumps is key to ensuring that the water treatment disinfection process runs smoothly.