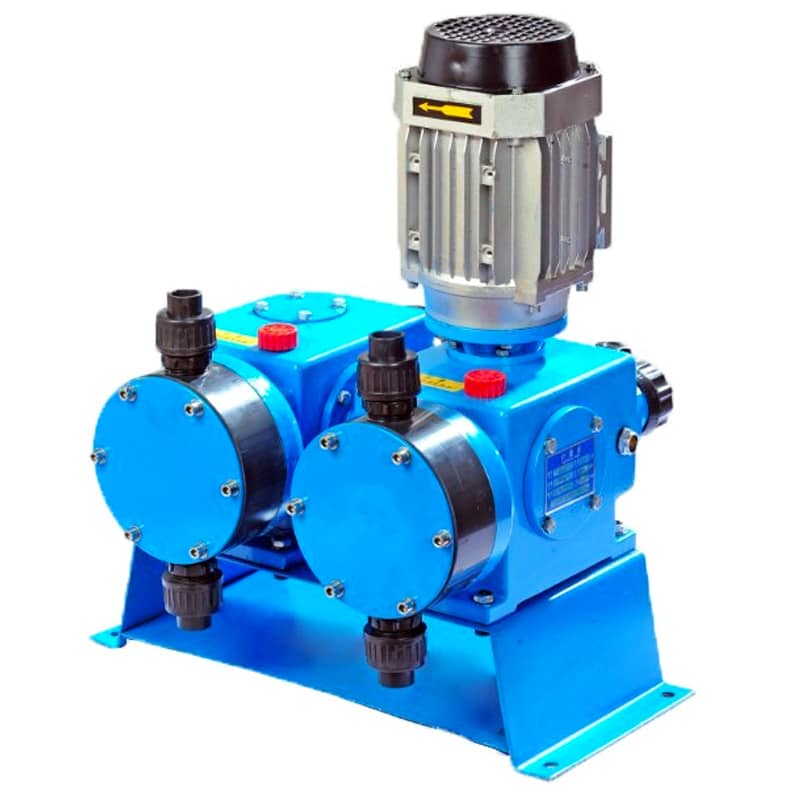

High Viscosity Metering Pump

A high viscosity metering pump is a specialized device for transferring high viscosity liquids, and its main function is to accurately meter and transfer high viscosity media. These pumps typically utilize specially designed pump bodies and moving parts to meet the challenges of highly viscous liquids and to ensure precise flow control and delivery.

Design features of high viscosity metering pumps

In order to accommodate high viscosity liquids, the pump body and pump chamber are usually designed larger to reduce the resistance of the liquid in the pump to achieve a smoother flow. The diameter of the pump shaft and pump lobe is usually increased accordingly to increase the pump’s carrying capacity and ability to withstand high viscosity liquids.

The transportation of high viscosity liquids requires high lubrication, so high viscosity metering pumps usually use special lubrication systems to ensure the smooth operation of moving parts. In order to prevent leakage of high viscosity liquids and improve sealing performance, the sealing structure of high viscosity metering pumps is usually optimized to ensure the sealing between the pump body and moving parts.

Advantages

Adaptation to high viscosity liquid: Designed for conveying high viscosity liquids, such as resins, glues, lubricants, etc., it can effectively cope with the characteristics of high viscosity media.

Corrosion resistance: made of corrosion-resistant materials, able to cope with the corrosive components that may exist in high viscosity liquids, to ensure the long-term stable operation of the equipment.

High stability: solid design, precision moving parts, excellent stability and reliability, in different working conditions can maintain a stable working condition.

Accurate dosing metering: Through the precise design of the pump body and flow control system, accurate flow metering can be realized to ensure precise control and quality assurance of the production process.

Disadvantages

Higher cost: Compared with ordinary pumps, high viscosity metering pumps usually have more complex design and manufacturing requirements, so the cost is higher.

Difficulty of maintenance: Because high viscosity metering pumps often need to deal with more corrosive liquids, so the pump maintenance and repair requirements are higher, maintenance is more difficult.

Possible risk of leakage: Due to the nature of highly viscous liquids, there may be an increased risk of leakage during transportation, requiring additional protective measures to ensure safety.

Summary

High viscosity metering pumps are indispensable and important equipment in modern industrial production, and their accurate metering and stable performance play a key role in many fields. By choosing the right high viscosity metering pumps, you can increase productivity, reduce costs and achieve a more reliable production process. HAOSH, as a leader in the water treatment industry, offers a wide range of high viscosity metering pumps, covering a variety of industrial applications, we are committed to providing our customers with high quality, high performance solutions to ensure the smooth running of the production process.