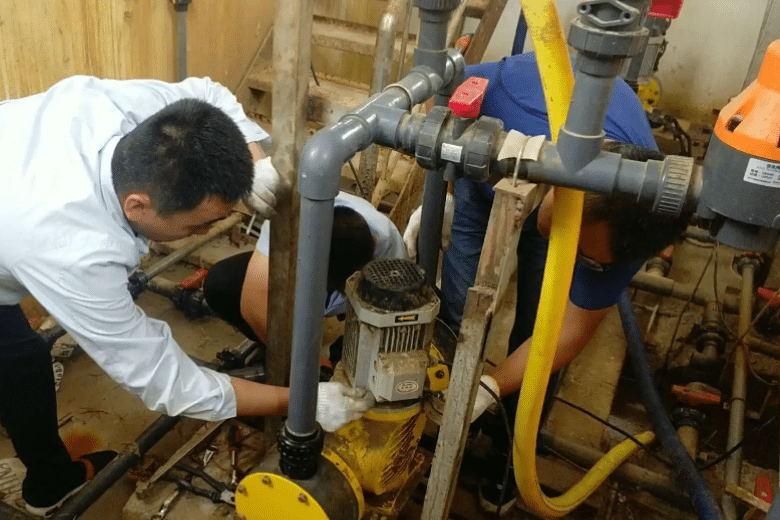

Dosing Pump Troubleshooting

Dosing pump troubleshooting plays a crucial role in maintaining the optimal performance of dosing systems across various industrial applications. As indispensable components in chemical dosing processes, dosing pumps ensure precise and accurate delivery of chemicals and additives, essential for achieving desired outcomes in water treatment, wastewater management, industrial processes, and more. However, like any mechanical system, dosing pumps may encounter issues that can disrupt operations and compromise efficiency. In this troubleshooting guide, we will explore common problems faced by dosing pumps and provide effective solutions to address them, empowering operators to swiftly diagnose and resolve issues, thereby ensuring continuous and reliable dosing operations.

Troubleshooting and solutions for dosing pumps

Below is a table of possible malfunctions and solutions for solenoid dosing pumps, mechanical dosing pumps, motor-driven dosing pumps, and pumps in general:

Solenoid dosing pump

| Issue | Solution |

| Power Supply Issue | 1. Check if the power connections and cables are loose or damaged, reconnect or replace damaged cables. 2. Ensure the power socket is functioning properly, try connecting to another socket. 3. Check if the power switch is turned on. |

| Control Circuit Fault | 1. Check if control circuit components such as fuses, relays, etc., are burnt, replace damaged components. 2. Reset control circuit parameters to ensure correct settings. 3. Check if control circuit connections are loose, reconnect if necessary. |

| Coil Burnout | 1. Check if the coil is damp or short-circuited, and replace damaged coils. 2. Check if the power voltage is too high, and install a stabilizer if necessary. 3. Check if the motor is overloaded during operation, reduce the load, or replace it with a higher-power motor. |

| Frequency/Voltage Instability | 1. Install a stabilizer or voltage regulator to ensure a stable power supply. 2. Check if the power supply grid is stable, and contact the power supply department if necessary to resolve grid issues. 3. Adjust electromagnetic control system parameters to adapt to power fluctuations. |

| Overheating | 1. Check if the airflow around the electromagnetic components is obstructed, remove any obstacles. 2. Ensure adequate ventilation and cooling devices around the electromagnetic components. 3. Monitor operating temperature and adjust operating parameters as needed to reduce overheating. |

H Solenoid Dosing Pump, HS Solenoid Dosing Pump and HH Solenoid Dosing Pump, these three dosing pump drives are virtually wear-free because there is only one moving part. The pumps do not require lubrication of bearings or shafts, so maintenance and repair costs are very low. The continuous operation characteristics are very good.

Mechanical dosing pump

| Issue | Solution |

| Suction Line Blockage | 1. Regularly inspect if the pump’s moving parts are worn, and replace worn parts promptly. 2. Add appropriate lubricants to reduce friction of moving parts. 3. Adjust the pump’s operating parameters to reduce the degree of wear on moving parts. |

| Valve or Seal Damage | 1. Check if valves and seals are worn or aged, and replace damaged parts. 2. Readjust the installation position of valves or seals to ensure sealing performance. 3. Select valves and seals made of wear-resistant materials to extend their service life. |

| Wear of Moving Parts | 1. Check if the suction line and filters are clogged with debris, clean the lines and filters. 2. Check if the suction valve is closed or damaged, readjust or replace the valve. 3. Check if the liquid concentration is too high, and dilute the liquid appropriately. |

| Pump Instability or Leakage | 1. Check if the pump’s base and installation fixtures are securely fastened, and re-fasten loose parts. 2. Check if seals are aged or damaged, and replace seals if necessary. 3. Adjust the pump’s operating parameters to reduce vibration and leakage. |

| Cavitation | 1. Regularly inspect if the pump’s moving parts are worn, and replace worn parts promptly. 2. Add appropriate lubricants to reduce friction of moving parts. 3. Adjust the pump’s operating parameters to reduce the degree of wear on moving parts. |

The HJ-Z Mechanical Dosing Pump and HJ-X2 Mechanical Dosing Pump combine the durability of hydraulic dosing pumps without the need for an intermediate fluid or hydraulic oil to drive the diaphragm.

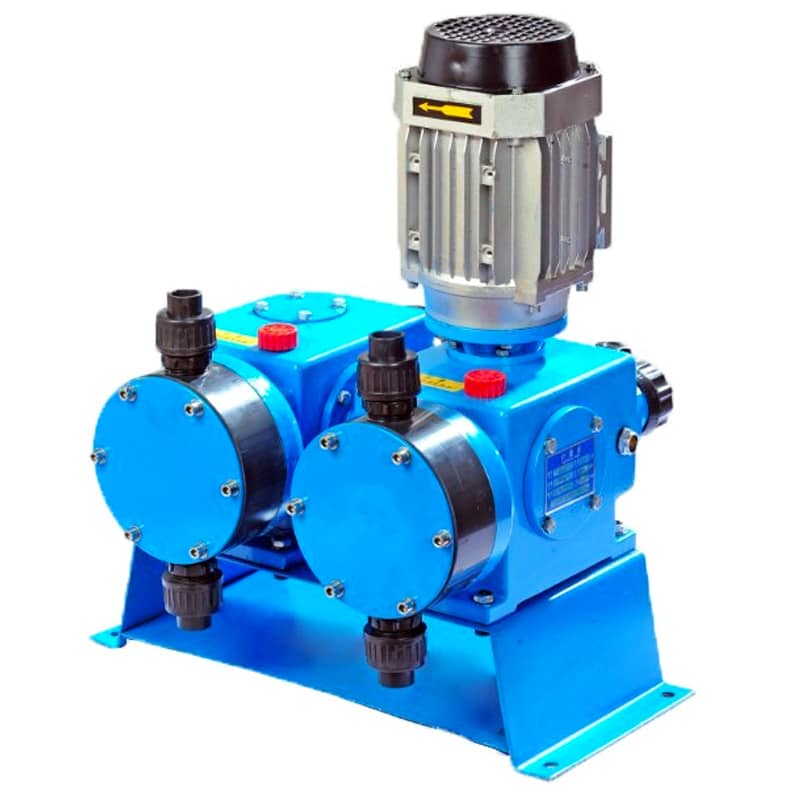

Motor-driven dosing pump

| Issue | Solution |

| Motor Fails to Start or Responds | 1. Check if power connections are loose or damaged, reconnect or replace damaged cables. 2. Check if the motor start button is pressed, ensure the control switch is turned on. 3. Check if the motor is damp or blocked, repair or replace the damaged motor if necessary. |

| Motor Overload | 1. Reduce the load, adjust the pump’s operating parameters to reduce motor load. 2. Check if the power voltage is too high, install a stabilizer if necessary. 3. Check if motor bearings and moving parts are worn, replace damaged parts as needed. |

| Abnormal Noise during Motor Operation | 1. Check if motor bearings are insufficiently lubricated, add appropriate lubricants. 2. Check if motor housing is loose, re-fix loose components. 3. Check if motor moving parts are worn, replace worn parts if necessary. |

| Motor Speed Instability | 1. Check if power supply is stable, install a stabilizer to ensure stable power supply. 2. Check if the motor controller is functioning properly, adjust motor speed or replace controller if needed. 3. Adjust motor operating parameters to improve speed stability. |

| Vibration | 1. Check if mounting bolts are loose or damaged, tighten or replace as needed. 2. Ensure proper alignment of motor and pump shafts, readjust alignment if necessary. 3. Check if motor or pump bearings are worn, replace damaged parts as needed. 4. Install vibration isolators or dampers to reduce vibration transmission. |

The HJ-D2 Mechanical Dosing Pump and the HJ-L Mechanical Dosing Pump are powered by an electric motor and have a controller that manages the flow rate, and are almost universally used in the low pressure range.

Hydraulic dosing pump

| Issue | Solution |

| Hydraulic Pump Fails to Start | 1. Check if the hydraulic pump’s power connections are secure, reconnect or replace damaged cables. 2. Ensure the power socket for the hydraulic pump is functioning properly, try connecting to another socket. 3. Check if the power switch is turned on. 4. Verify that the pressure valve of the hydraulic pump is functioning properly, ensuring it is in the open position. |

| Inconsistent Flow of Hydraulic Pump | 1. Check if the inlet and outlet pipelines of the hydraulic pump are blocked, clean the pipelines and ensure they are clear. 2. Verify if the hydraulic pump’s fluid level is too low, add sufficient fluid to ensure proper operation. 3. Adjust the hydraulic pump’s operating parameters, such as flow control valves, pump speed, etc., to accommodate flow variations. |

| Pump Pressure Too High or Too Low | 1. Check if the pressure regulating valve of the hydraulic pump is set correctly, adjust appropriately to meet pressure requirements. 2. Inspect if the inlet and outlet pipelines of the hydraulic pump are properly connected, ensuring pipelines are clear. 3. Verify if the seals of the hydraulic pump are intact, replace seals if necessary. 4. Check if the inlet and outlet valves of the hydraulic pump are functioning properly, readjust or replace valves. |

| Unusual Noise from Hydraulic Pump | 1. Check the lubrication of the hydraulic pump, add adequate lubricants to reduce friction and noise. 2. Inspect if the hydraulic pump’s body is loose, re-fix any loose components. 3. Examine if the moving parts of the hydraulic pump are worn, replace damaged parts as necessary. |

| Pump Leakage | 1. Check if the seals of the hydraulic pump are worn or aged, replace damaged seals. 2. Inspect if the fastening bolts of the hydraulic pump are loose, re-tighten any loose bolts. 3. Adjust the hydraulic pump’s operating parameters, such as pressure regulating valves, seals, etc., to minimize leakage. |

The HY-Z Hydraulic Dosing Pump, HY-ZR Hydraulic Dosing Pump, HY-D Hydraulic Dosing Pump and HY-D2 Hydraulic Dosing Pump combined with hydraulic drive configurations make it easy to achieve the high-pressure dosing required, and are particularly well suited for applications where corrosive, toxic, and flammable liquids are dosed at very high pressures and extreme temperatures.

Other troubleshooting problems and solutions for dosing pumps

In addition to the troubleshooting problems and solutions listed above, several other problems can occur, such as:

- Chemical compatibility problems: Certain chemicals may not be compatible with the internal materials of the dosing pump, resulting in corrosion or deformation of the materials, which in turn affects the performance and life of the pump.

- Operational errors: The operator may have mistakenly set the pump parameters, such as flow rate, pressure, etc., causing the pump to fail to work properly or work erratically.

- Environmental conditions: the pump is located in environmental conditions such as temperature, humidity, pressure, etc. may be beyond the design range of the pump, affecting the performance and stability of the pump.

- Improper maintenance: Regular maintenance of the pump may be neglected, such as lubrication, cleaning, fastening, etc., resulting in increased wear and tear of pump components and performance degradation.

- Power supply problems: The pump receives a power supply that may have problems, such as unstable voltage, grid failure, etc., affecting the normal operation of the pump.

- System failure: The system integrated with the pump, such as controllers, sensors, etc., may be faulty, resulting in the pump not working properly or working abnormally.

- Pump parts aging: After a long time of use, some key parts of the pump such as seals, valves, etc. may appear aging or damaged, and need to be replaced to ensure the normal operation of the pump.

These problems may affect the normal operation and performance of the dosing pump performance, so in the use of dosing pumps, operators need to pay close attention to the pump’s working status and take appropriate measures to solve the problem promptly.

Summary

Through effective troubleshooting and solutions, we can ensure the stable operation of dosing pump systems, thus guaranteeing the smooth running of critical processes such as water treatment, wastewater management, and industrial production. Timely maintenance and attention to problem identification not only improve productivity and reduce unplanned downtime, saving costs for the organization but also contributing to environmental protection and sustainable development.

HAOSH specializes in the development of dosing metering pumps and systems that can provide you with more perfect solutions, we also offer accessories, mixing agitators and dosing systems. Please feel free to contact us if there is any need.