Mixer Agitator

Mixer agitator is a machine used in a tank to mix various process media together. The types of media include liquids, gases and solids. It works by rotating an impeller that transfers energy to the interacting and mixing media. The components of the mixer are usually the motor and gearbox, shaft and impeller selected for the job.

Typical applications are, for example, chemical mixing in water treatment dosing tanks, agitation and aeration in aeration tanks, static mixer for mixing various materials, etc.

Uses of agitator Mixers

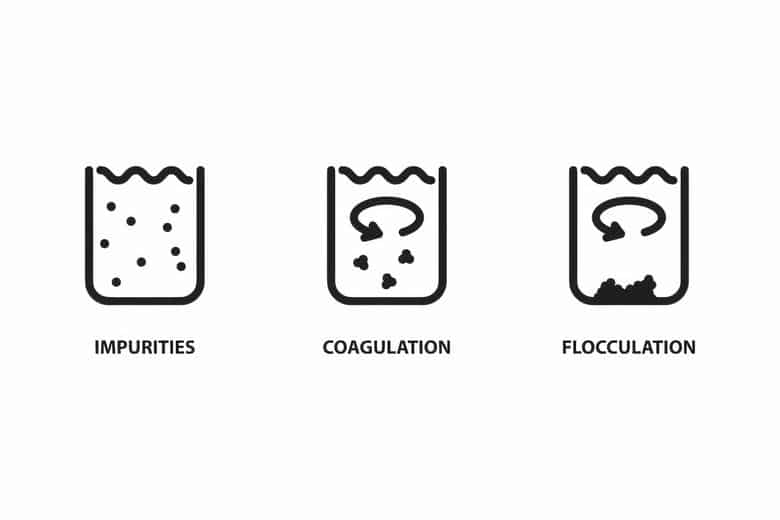

Agitators are used to mix liquids, gases and solids in different process media – chemical additions or pharmaceutical ingredients. Agitators transfer energy by mechanical means through a rotating shaft with an impeller specifically designed for that task. This may be axial pumping, gas induction, flocculation, high viscosity products, high and low shear mixing, etc.

In wastewater treatment, you need precise mixing control at every stage, from rapid flash mixing to polymer addition. While some chemicals only need to be dissolved, others (such as lime slurry) require special attention to solids, mass transfer and reactions in the neutralization phase of the process.

Examples of new and older processes requiring controlled mixing methods include moving bed bioreactors (MBBR), aerobic and anaerobic processes. Our expertise in mixing allows these processes to benefit from the energy efficiency of top inlet mixers. Our mixers are designed to meet the complex needs of your wastewater treatment process.