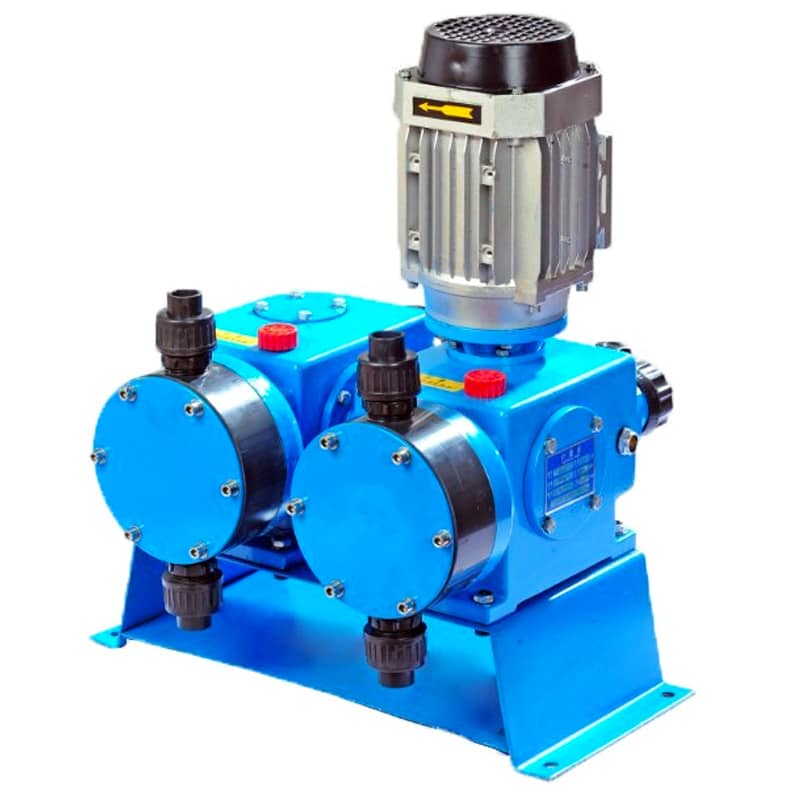

High Pressure Dosing Pump

High pressure dosing pumps are pumps that are used to transfer chemicals or liquids and are characterized by their ability to operate in high pressure environments. These pumps are typically used in applications that require high accuracy and pressure, such as water treatment, chemical, and oil and gas industries. They can provide consistent flow and pressure under varying operating conditions, ensuring accurate dosing and mixing of chemicals.

Working Principle

The principle of operation is similar to that of a regular dosing pump, but they are capable of generating higher pressures to meet the needs of specific applications. They are typically made of corrosion-resistant materials to accommodate different chemicals and liquids and are equipped with sophisticated control systems to ensure that they provide stable and reliable operation under a wide range of operating conditions.

Advantages

High precision

High reliability

High efficiency

Disadvantages

High cost

High energy consumption

Difficult maintenance

Noise and vibration

High-pressure dosing pumps are a key piece of equipment widely used in many industrial applications that can deliver high pressure liquids and provide precise flow and pressure control. Although high-pressure dosing pumps have some drawbacks, when correctly selected and used, they are useful for pumping chemicals and injecting them into the process stream to ensure accurate chemical injection. They can provide a reliable solution for a variety of applications.