Chemical Dosing Water Treatment

Chemical dosing water treatment is a critical process in ensuring water quality and safety across various applications, from municipal water purification to industrial wastewater management. By precisely adding chemicals such as disinfectants, coagulants, and pH adjusters, this method enhances the removal of contaminants, prevents scaling and corrosion, and maintains regulatory compliance. With advancements in dosing technology, modern water treatment systems achieve higher efficiency, sustainability, and cost-effectiveness.

What is chemical dosing water treatment?

Chemical dosing has applications in a variety of industries, from wastewater treatment to petrochemicals. Chemical metering refers to the delivery of chemicals to fluids. When applied to wastewater treatment, it is used in the anaerobic digestion process to extract energy from the waste and return clean effluent to natural waterways.

Pumped chemicals are often expensive, so its entire process needs to be precisely metered and controlled.

Ensuring that you have an accurate and powerful chemical injection pump is a priority. A quality metering pump can save you money on operating costs.

In the case of wastewater sludge, for example, chemical dosing adds chemicals to the water or sludge to achieve the desired conditioning. This will allow treatment to be effective through various mechanisms such as charge neutralization, solids settling, etc., helping to speed up the treatment process and save project costs.

Why is Chemical Dosing Important in Water Treatment?

- Disinfection: Utilizing chemicals like chlorine or hypochlorous acid to eliminate pathogens in drinking water, ensuring safety for consumption.

- pH Adjustment: Adding acids or alkalis to maintain optimal pH levels, crucial for effective coagulation and precipitation processes.

- Coagulation and Flocculation: Introducing coagulants such as aluminum sulfate to aggregate suspended particles, facilitating their removal.

- Scale and Corrosion Control: Dosing inhibitors to prevent scale formation and corrosion in pipelines and equipment, thereby extending their operational lifespan.

- Odor Control: Applying chemicals like potassium permanganate to neutralize unpleasant odors caused by hydrogen sulfide in wastewater.

Selecting the right chemical dosing pump

Compatibility with the pumped substance

Many chemicals exhibit high reactivity and corrosiveness, potentially compromising the integrity of materials such as plastics and metals used in dosing equipment. Therefore, it is essential that a chemical metering pump is made of a suitable material that can handle the chemicals properly.

| Material Compatibility | Suitable Chemicals |

| Stainless Steel | Acids, Alkalis |

| PVC | Chlorine, Hypochlorous Acid |

| PTFE | Solvents, Corrosive Chemicals |

Durability

Durability and longevity are two important components in finding the best productivity in any part that can serve you for a long time.

Accuracy

Chemical dosing is a precision field that requires high accuracy and repeatability. The chemical market is an expensive one, so a metering pump that can repeatedly deliver quality service will ensure your process is up to par, which will save you a lot of money and take the stress out of the future.

The right chemical metering pump will benefit your overall processing program. Look for a metering pump that is compatible with your chemistry because it will provide accurate results in a consistent time frame, and more importantly, look for an extremely durable pump such as the chemical metering pumps manufactured by HAOSH.

- Solenoid diaphragm dosing pumps

- Mechanical diaphragm dosing pumps

- Hydraulic diaphragm dosing pumps

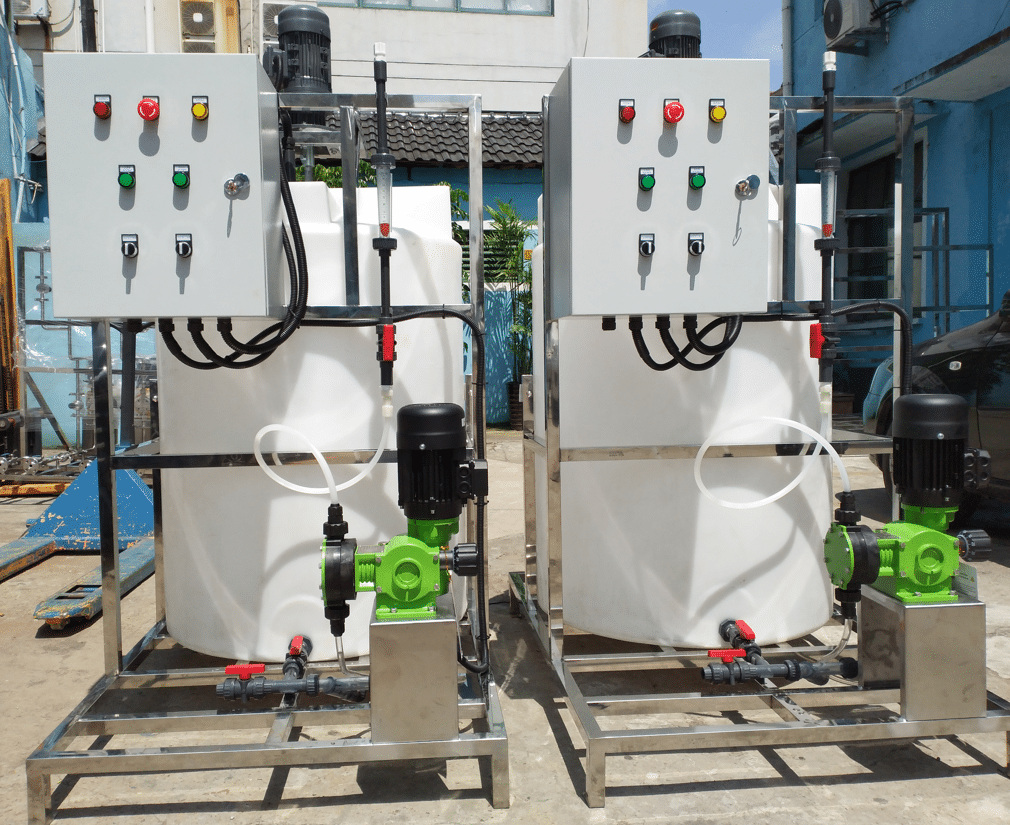

- Chemical dosing systems

Summary

HAOSH offers you a total solution for dosing and metering, handling all aspects through design, requirements, parts, field and customer support. Contact HAOSH for an equipment quote or to inquire about solutions.