Calibration Columns in Water Treatment

What is a calibration column?

A calibration column is a device used to calibrate and verify the accuracy of an instrument or piece of equipment. It is usually a long, narrow, transparent tube that is used to hold a standard liquid or gas of known concentration for comparing and calibrating the output of an instrument.

What is the use and importance of calibration columns?

- Calibration and verification of instrument accuracy:

Provide standard reference material: The standard liquid or gas in the calibration column has a known concentration or property and is used as a standard reference material for the instrument or sensor to calibrate and verify the output of the instrument. - Monitor instrument operating status:

Real-time monitoring: Calibration columns allow real-time monitoring of the output results of an instrument or device. By observing changes in the level or bubbles in the calibration column, the working status and accuracy of the instrument can be monitored. - Adjust and calibrate the equipment:

Adjusting the instrument: Comparing the changes of the standard liquid or gas in the calibration column and the output results of the instrument, the instrument can be adjusted to ensure that its output is consistent with the standard. - Ensure measurement accuracy:

Ensure accuracy: The use of calibration columns ensures that the instrument provides accurate and reliable results in measurements and tests, avoiding errors and uncertainties. - Quality control and compliance:

Compliance with standards: In some industries, the use of calibration columns is part of quality control and regulatory compliance, ensuring that instruments and equipment meet relevant standards and regulations.

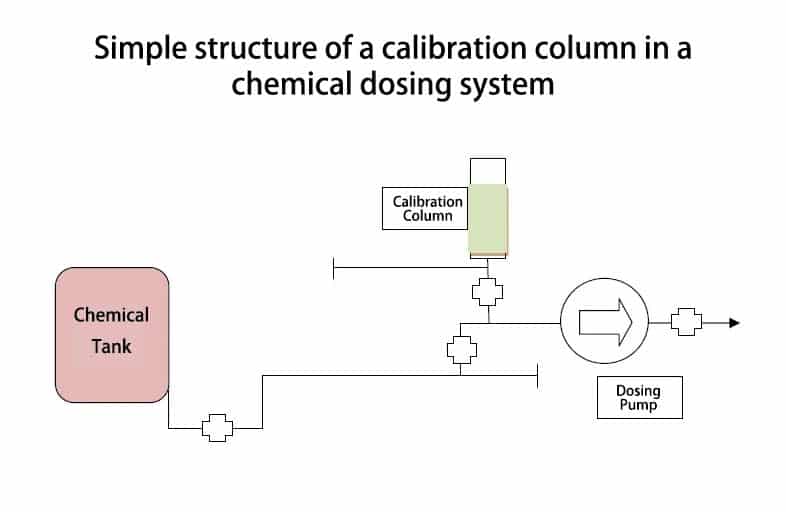

Relationship between calibrated columns and dosing metering pumps

Calibration columns and dosing metering pumps complement each other in a dosing system. The calibration column acts as a calibration and monitoring device to ensure the accuracy and stability of the output of the dosing metering pump to ensure proper system operation and accurate dosing.

- Calibration process: The calibration column is used to verify the output of the dosing metering pump. During the initial installation and commissioning phase, the output and accuracy of the dosing metering pump is calibrated by observing the level changes in the calibration column.

- Monitoring and verification: The calibration column can still be used to monitor the operating status and output of the dosing metering pump(HJ-Z Mechanical Dosing Pump) after the system has been operated. It can be used as a checking device to verify that the dosing metering pump is outputting the agent as expected.

- Fault detection: Abnormal calibration column level changes may indicate a problem with the dosing metering pump, such as abnormal flow, bubbling, or stalling. This condition may require inspection and adjustment of the dosing metering pump.

Does the conveyed fluid pass through the calibration column?

Typically, calibration columns are not used to convey liquids directly. Calibration columns are tools used to calibrate and verify the accuracy of liquid handling equipment (e.g., pumps, metering devices, flowmeters, etc.) and are not intended for use in piping or tubing for the delivery of liquids.

The primary function of a calibration column is to provide a standard solution of known concentration for instrument calibration and verification, and is usually placed in the calibration section of the equipment or in the piping connected to the equipment, rather than as part of the piping that actually delivers the liquid. It is used to verify the difference between the instrument output and the expected value and to ensure accuracy by adjusting the equipment.

Therefore, a calibration column is not typically used as part of the actual fluid delivery, but as part of a calibration system to calibrate and verify the accuracy of the equipment.

What’s in the calibration column?

Calibration columns are usually filled with a standard liquid or gas of known concentration and are used to calibrate and verify the accuracy of instruments. The exact substance loaded depends on the need for calibration and the type of equipment used, for example:

Type of substance loaded in the calibration column:

- Standard liquid:

A solution of known concentration: for example, a standard salt solution, a standard acid-base solution, or a standard solution of a specific chemical. These solutions have known concentrations and are used to calibrate and validate analytical instruments, such as chromatographs, spectrometers, and so on. - Standard gases:

Gas mixtures: standard gas mixtures used to calibrate gas sensors or gas analyzing instruments. These gas mixtures usually contain known concentrations of gases such as oxygen, nitrogen, carbon dioxide, etc. - Other standard samples:

Samples of Known Properties: In some specific instruments, samples of known properties may be used, such as standard samples for mass spectrometers or other specific equipment.

What is the scale of the calibration column?

The scale of a calibration column usually depends on the specific equipment or experimental requirements being used for calibration. It may be calibrated and scaled in milliliters, pressure units, concentration ratios, level heights, and so on.

For liquid level calibration columns, the scale may represent concentration or pressure values corresponding to different liquid level heights. For example, each scale represents a level height that may correspond to a specific concentration of standard solution or pressure value.

In the case of gas calibration columns, on the other hand, the scale may be in units of gas pressure or volume to indicate pressure values for different concentrations of gas mixtures or standard gases.

The unit notation of a calibration column usually depends on the physical quantity it is measuring or calibrating. For example, a liquid level calibration column may use the notation of the unit of length in millimeters (mm), centimeters (cm), meters (m), etc. to indicate the height of a liquid level. Gas calibration columns may use symbols for units of pressure, such as Pascals (Pa) or other units of barometric pressure.

Summary

Calibration columns play a key role in scientific experimentation, healthcare and industrial production, ensuring the accuracy and reliability of instruments and equipment. Their role as a standard reference for calibrated instruments ensures data accuracy and provides a solid foundation for progress and quality control in all fields.

HAOSH specializes in the development of dosing metering pumps and systems, offering dosing metering pumps, pump accessories, mixers and dosing systems. Welcome to contact us anytime.