Application Of Pumps In Flocs Treatment

The Importance and Applications of Flocs

What are flocs?

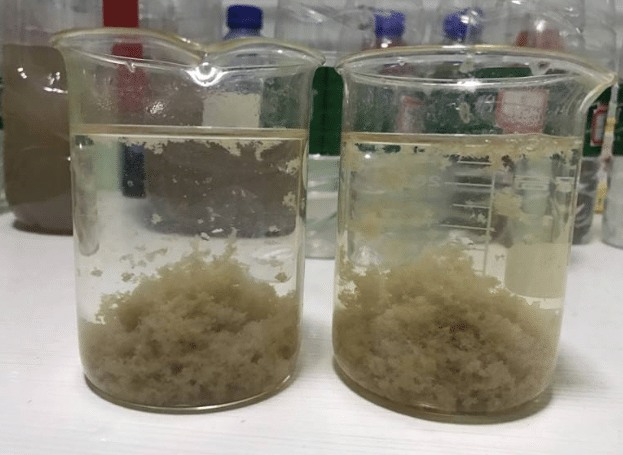

Flocs are clumps or sediments of tiny suspended particulate matter that form in water. It is usually composed of suspended particles, colloidal substances and organic matter in water. These particulate matter come together through chemical reactions or physical action to form visible clumps or precipitates.

The importance and application fields of floc

Flocs play an important role in water treatment and environmental protection.

- Water treatment: Flocs can help remove suspended particles, organic matter, color and turbidity in water and improve water quality. During water treatment, floc is often used to purify and clarify water, making it more suitable for drinking, industrial use, or environmental discharge.

- Sewage treatment: Flocs play an important role in sewage treatment. They help to remove suspended solids, suspended particles and organic matter in sewage, purify sewage and reduce pollution to the environment.

- Mining and mineral processing: In mining and mineral processing, flocs can help separate solid particles, minerals and impurities in ore, thereby improving the purity and usability of the ore.

- Papermaking and Textile: Flocs are used in the papermaking and textile industry to remove suspended solids and colors in wastewater, purify wastewater and reduce the impact on the environment.

- Food and beverage processing: In food and beverage processing, flocs are used to clarify liquids, remove turbidity and color, and make products clearer and more aesthetically pleasing.

Flocs play an important role in water treatment and other fields, helping to improve water quality, protect the environment and improve product quality.

The difference between flocs and flocculants

Flocs and flocculants are two related but different concepts in water treatment.

Flocs refer to the aggregation of suspended particles in water through the action of flocculants. They are aggregates of suspended matter particles of variable size and are usually larger for easy settling or separation.

Flocculants are chemical substances that promote the formation of flocs by changing the chemical properties of the water body. Under the action of flocculant, the attraction between suspended particles increases, so that they aggregate to form flocs.

What are the types of flocs?

The type of floc mainly depends on the nature of the suspended matter in the water body and the goal of water treatment.

Organic Flocs:

- organic polymers

- humus

- proteins

Inorganic Flocs:

- iron

- aluminum

- calcium and other metal hydroxides

- silicates

Biofloc:

- microorganisms

- algae

Different types of flocs have different effects on the water treatment process and subsequent treatment steps, so selecting the appropriate flocculant and controlling the formation of flocs are crucial. By adjusting the type, dosage and dosage of flocculants, the formation and aggregation of flocs can be effectively controlled, thereby improving water quality and treatment effect.

The purpose of floc dosing

The purpose of floc dosing is to promote the aggregation and settlement of suspended solids in the process of water treatment, so as to realize the clarification and purification of water body.

- Aggregation of suspended solids: The addition of flocculants can change the surface charge and interaction force of suspended particles in the water body, causing attraction between particles and promoting their aggregation into larger flocs.

- The increase of coagulation: Under the action of flocculant, the originally tiny suspended particles aggregate to form larger flocs, increasing their size and settling velocity, which facilitates subsequent solid-liquid separation.

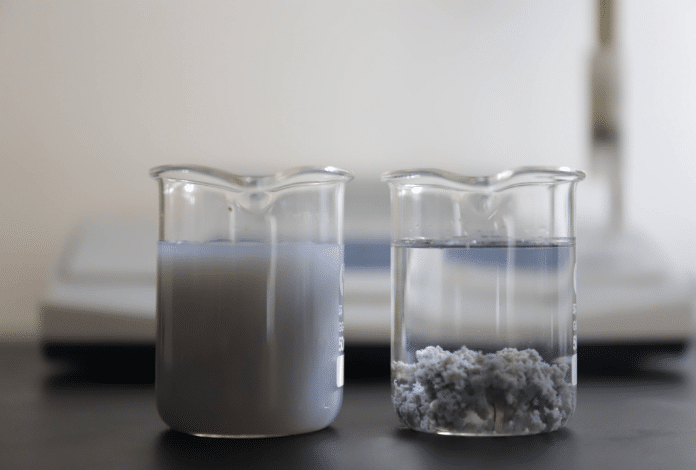

- Improve the clarification effect: The formation of flocs allows the suspended matter in the water to gather and gradually settle, thereby significantly improving the turbidity and clarity of the water body, making the water clear and transparent.

- Removal of suspended solids and pollutants: Suspended solids, particulate matter, turbidity substances, partially dissolved organic matter, heavy metals and other pollutants in the water are gathered in the flocs, and these pollutants can be effectively removed through the formation and settlement of flocs. Improve water quality.

Dosage range of floc and applicable pump type

| Floc Type | Recommended Dose Range (mg/L) | Applicable Pump Type |

| Polyacrylamide | 0.1-1 | Centrifugal pumps, diaphragm pumps, vortex pumps, peristaltic pumps |

| Potassium Permanganate | 1-10 | Centrifugal pumps, diaphragm pumps, vortex pumps |

| lime | 10-100 | Centrifugal pumps, diaphragm pumps, vortex pumps |

| Activated Carbon | 10-100 | Centrifugal pumps, diaphragm pumps, vortex pumps |

| Silica Gel | 0.5-5 | Centrifugal pumps, diaphragm pumps, vortex pumps |

| Coagulant | 1-10 | Centrifugal pumps, diaphragm pumps, vortex pumps |

| Aluminum Sulfate | 1-10 | Centrifugal pumps, diaphragm pumps, vortex pumps |

| Lron Chloride | 0.5-5 | Centrifugal pumps, diaphragm pumps, vortex pumps |

| Aluminum salt | 2-20 | Peristaltic pump, centrifugal pump |

| Iron Salt | 1-10 | Peristaltic pump, centrifugal pump |

| Organic Flocculant | 0.5-5 | Centrifugal pump, diaphragm pump |

| Polymer Flocculant | 0.1-1 | Diaphragm pumps, centrifugal pumps, vortex pumps |

| Natural Floc | 5-50 | Centrifugal pumps, diaphragm pumps, vortex pumps, peristaltic pumps |

Risk of clogging pumps with flocs

When flocs form clumps in the water, they may deposit or attach to internal parts of the pump, causing clogging or reducing pump efficiency.

Blockage of pump internal components: Large amounts of floc can form blockages in the inlet and outlet sections of the pump, preventing the smooth flow of fluid. This may cause the pump to run poorly or stop completely.

Floc Attachment: Certain types of floc may adhere to the pump’s blades, rotor, or inner walls, forming sticky deposits. This causes the pump rotors to run hard, reducing pump efficiency and increasing energy consumption.

Pump damage: If a large amount of floc enters the key parts of the pump, such as mechanical seals or bearings, they may cause damage or wear of the pump, resulting in reduced performance or failure of the pump

It is very important to choose a suitable metering pump to transport flocs. Our product H series electromagnetic metering pump is a good choice, it is corrosion-resistant and relatively cheap.

Choose the right transfer pump

The pump that transports the floc plays a key role in disposing of the floc. Choosing the right pump type for floc handling and proper maintenance can ensure an efficient transfer and disposal process.

Below are some pump types suitable for handling flocs and related pump selection and maintenance considerations:

- Diaphragm pumps: Diaphragm metering pumps are one of the pump types commonly used to transport liquids with high solids content. They are corrosion resistant and have good self-priming capabilities to effectively handle liquids containing flocs. When choosing a diaphragm pump, attention should be paid to selecting the appropriate material to ensure its corrosion resistance, and the electromagnetic metering pump can meet most of the delivery needs.

- Dosing metering pump: It adopts sophisticated metering mechanism and control system, which can accurately control the dosage of medicines and ensure the accuracy and stability of medicines addition. The flocculant or other agents can be accurately dosed into the liquid to promote the aggregation of flocs and form larger particles for subsequent treatment and filtration.

- Chemical dosing system: The dosing metering pump can usually be integrated with the dosing automation control system to achieve precise dosing control and remote monitoring.

- Motor-driven metering pump: It is a plunger metering pump driven by electric motors. The flocs often have certain viscosity and particle properties, which can easily cause blockage or wear of the pump, thus affecting the performance and stability of the pump. The metering pump driven by the motor has a certain degree of wear resistance and anti-clogging ability. Our product HJ-Z series pumps can be used to transport some low-viscosity flocs. The pump adopts mechanical metering method, and realizes the delivery and metering of fluid through the reciprocating movement of the piston.

- Peristaltic pumps: Peristaltic pumps are another pump type suitable for handling flocs. They use a peristaltic motion to push the liquid from the inlet to the outlet and are capable of transferring liquids with high solids content and high viscosity. When choosing, consider the viscosity of the liquid and the size of the solid particles, and replace the fittings regularly to ensure their normal operation.

- Centrifugal pumps: Centrifugal pumps can also be used to transport flocs in some cases, but care should be taken to select special models suitable for high solid content and corrosive liquids. Regularly cleaning the inside of the pump and inspecting the vanes for clogging or corrosion are important steps in pump maintenance.

No matter which pump type you choose, the internal parts of the pump will need to be inspected and maintained regularly to keep them functioning properly. This includes cleaning the pump inlet and outlet, replacing worn or damaged parts, keeping the pump properly lubricated and cooled, and monitoring the pump’s operating status. Regular maintenance will extend the life of the pump and ensure its efficient operation when handling flocs.

Summary

Flocs play an important role in many industrial and environmental applications, and are important for improving treatment efficiency, purifying liquids, and protecting equipment. Effective treatment of flocs requires the selection of suitable flocculants and the use of appropriate pumps to ensure efficient flocculation and treatment. In addition to providing pumps, HAOSH also provides pump accessories, agitators and dosing systems, etc. Please contact experienced engineers who will provide you with technical support and solutions.